Quality management on the comber

On cards and draw frames, sliver levelling and sliver quality monitoring are standard. Why not on the comber? We asked ourselves the same question and carried out corresponding developments.

TCO 12 – the only comber with levelling system

The Toyota-Truetzschler Comber TCO 12 is the only comber with integrated levelling system. This is made possible by the multi drive concept. The combed slivers are permanently monitored and the main draft in the drafting system is accordingly adapted. Thus, sliver count deviations due to differences in lap weight do not stand a chance.

TCO 12 – The only comber with quality monitoring

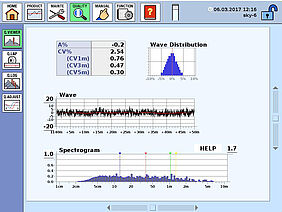

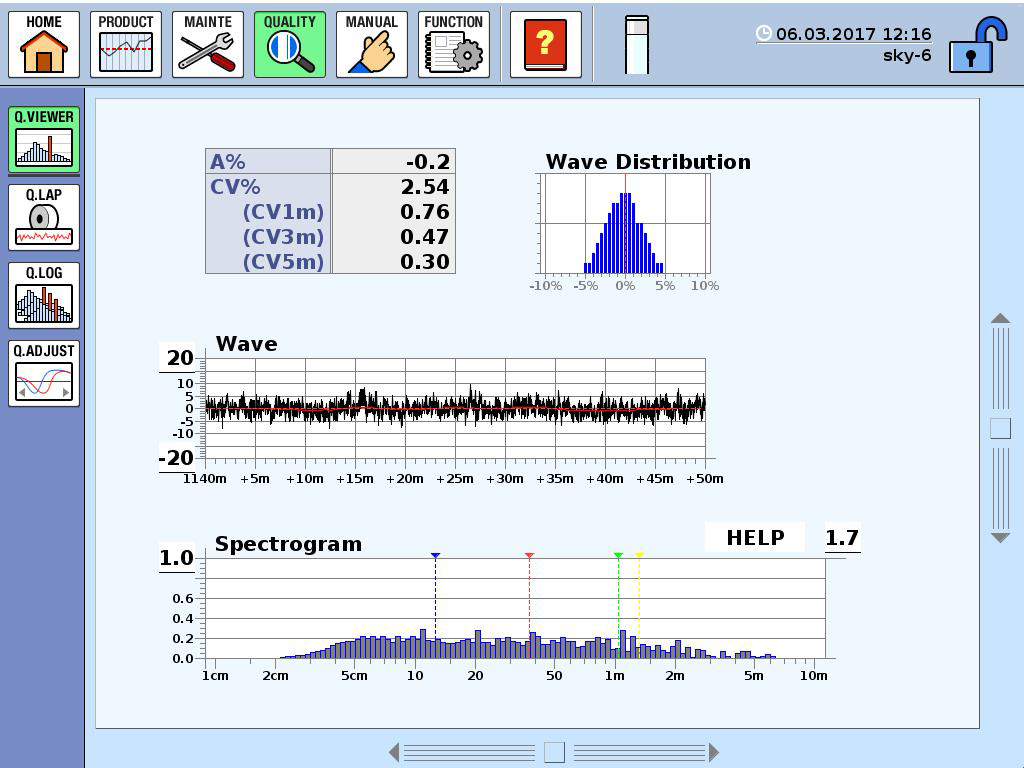

The quality sensor of the levelling system also supplies the signal for permanent quality monitoring of sliver evenness. The results are displayed in form of graphs and spectrograms on the large touch screen.

TCO 12 – The only comber with automatic piecing optimisation

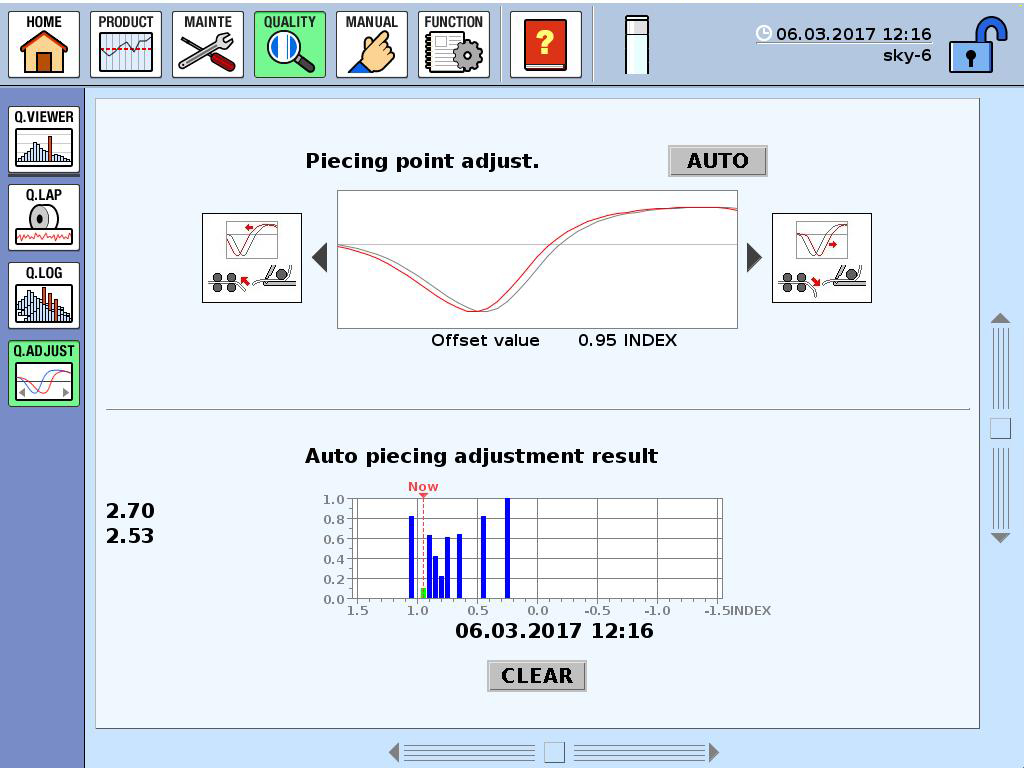

Correct setting of the piecing is a tedious process and requires a lot of time, know-how and laboratory capacity.

On the Toyota-Truetzschler Comber TCO 12 all it takes is the push of a button. The machine automatically checks the area around the set value and evaluates the sliver quality. After just a few minutes the machine determines at which setting the optimal sliver evenness and a clean spectrogram is achieved.

TCO 12 and T-DATA

Of course it is also possible to transmit all quality data of the TCO 12 to the higher-level data monitoring and management system T-DATA. Here they are also available for long-term analyses