New draw frame concept

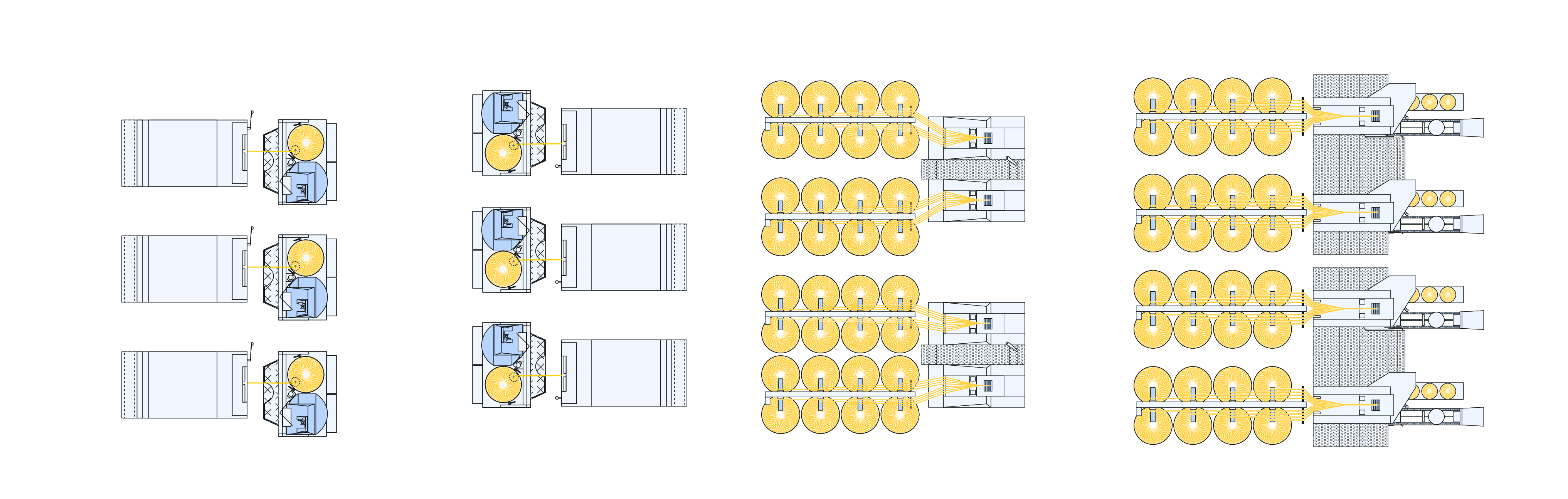

TWIN draw frame - this is what the new Trützschler Breaker Draw Frame TD 9T is called. TWIN means: A draw frame with two deliveries, but not based on the traditional double head principle. The advantage of low space requirement has been maintained. However, the disadvantage of the double head draw frames, poor efficiency, has been eliminated.

Higher efficiency

The TWIN draw frame TD 9T has two independent production sides. If a standstill occurs on one side, the other side continues producing. This also applies to the can changer. When one can is full, it is changed. There is no need to wait until the other can is full as well. There is no coupling efficiency between the two sides.

Flexible applications

With this concept it is even possible to produce different qualities on both sides. In a small air-jet spinning mill, the TD 9T operates on one side as blending draw frame and on the other side as second passage.

Reduced production costs

The TWIN draw frame has been designed for the application of JUMBO CANS with 1,200 mm diameter.

This applies to can set-up in the creel and at the delivery side. These cans hold 43% more sliver than conventional 1,000 mm cans. This means less sliver piecings and significantly less can transports.

Easy operation

Both draw frame sides are operated from a platform that is located in the middle. This saves space and reduces the walking distances for operators. The colour touch screen makes operation simple and effective.