Efficient production of cotton nonwovens with Trützschler carding technologies

Cotton and natural fibers account for 5 to 10% of the annual production of nonwovens. They are mainly used in premium wipes, baby and feminine hygiene products, and medical wound care. Cotton is expensive but has a very strong image. End products with the typical “cotton touch” are especially in demand in Asia.

Cards and carding machines from market leader Trützschler process bleached and unbleached raw cotton as well as comber noils. Even very short cotton linters can be used in multilayer cotton pads.

What needs to be considered when processing cotton fibers?

Different fiber lengths: Machine geometries must be selected so that long fibers are not pinched and short fibers are precisely carded.

Short fibers: Risk of fiber fly, which can lead to fiber accumulations and thus to non-uniform webs and increased cleaning effort.

Neps: These fiber knots are signs of aggressive or insufficient opening, unsuitable carding settings, or excessive speeds. Process parameters must be precisely matched to the fiber material.

Cotton nonwovens are

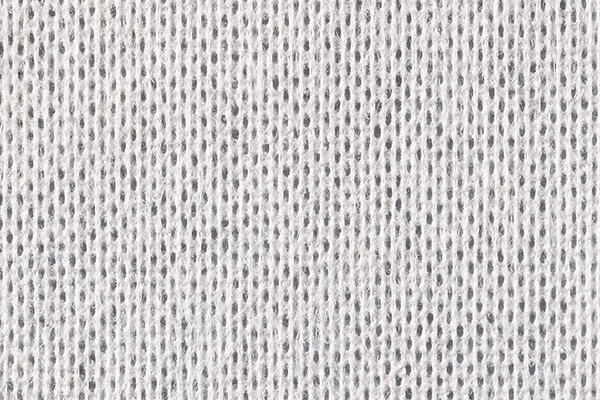

FUNCTIONAL

Absorbent with excellent dirt pickup; skin-friendly; strong in both dry and wet conditions

SOFT

Natural feel that users associate with purity, comfort, and naturalness

SUSTAINABLE

Plastic-free, 100% biodegradable, made from renewable raw materials or waste fibers (comber noils)

TWF-NCR random card

Bulky webs/nonwovens with excellent machine direction (MD) and cross direction (CD) strength

TWF-NCA airlay card

Isotropic nonwovens made from short and long fibers; ideal as filler material for cotton pads

TC hygiene cards by Trützschler Spinning

Special cotton cards for the production of cotton pads or multi-layer wipes

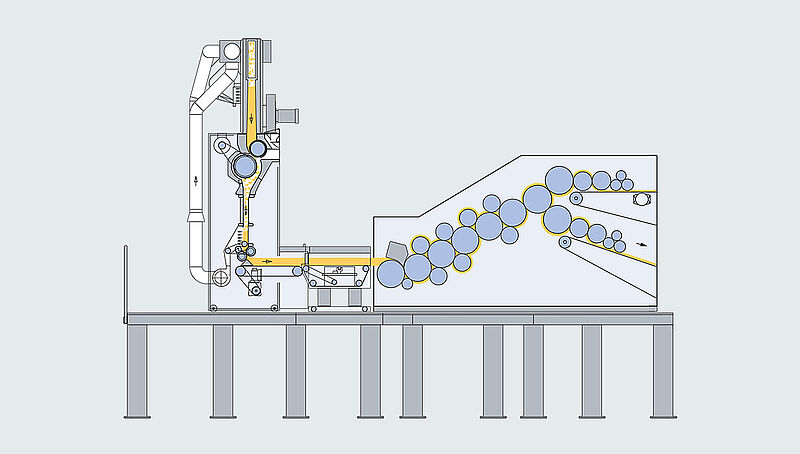

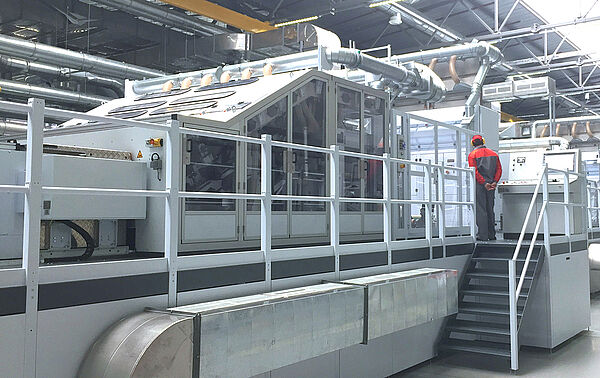

Random card TWF-NCR

The NCR card enables highly efficient processing of raw materials with varying fiber lengths and gentle carding, even with a high proportion of short fibers.

- Large carding area: double-sided carding via a series of carding and worker rollers

- Gentle opening of fiber tufts

- Dynamic web formation via tambour, doffer, and air guide plate – resulting in a bulky, soft random web with excellent MD/CD ratio

- Significantly reduced nep formation compared to conventional worker/stripper configurations

Technical data

- Suitable for raw cotton and comber noils, natural fibers and (recycled) man-made fibers

- Fiber length: 14 – 60 mm

- Web weight: 25 – 140 gsm

- Web bonding via hydroentangling/spunlacing or needle-punching

- Compatible with inline and crosslapper installations

- Clean Card Concept with enclosed design, precise sealing, and controlled extraction

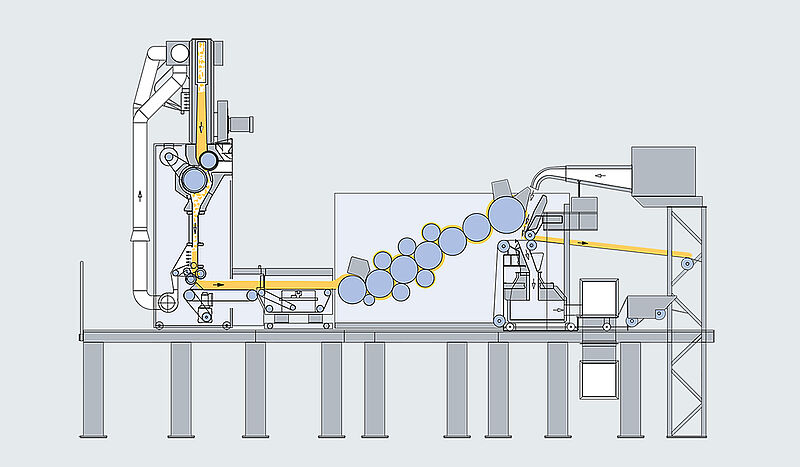

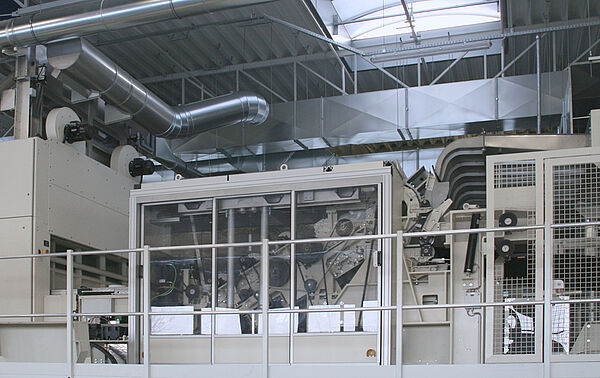

Airlay card TWF-NCA

The NCA card processes short and long fibers up to 60 mm into webs for nearly isotropic nonwovens. Even waste fibers from opening, combing, or flat top cards can be turned into high-quality end products:

- Large carding area: double-sided carding via a series of carding and worker rollers

- Gentle opening of fiber tufts

- Aerodynamic web formation via directed air stream

- Significantly reduced nep formation compared to conventional worker/stripper configurations

Technical data

- Suitable for raw cotton and comber noils, natural fibers and (recycled) man-made fibers

- Fiber length: 12 – 60 mm

- Web weight: 20 – 400 gsm

- Can be used standalone or in combination with NCR, NC-X, NCT-X, or flat top cards

- Web bonding via hydroentangling/spunlacing or needle-punching

- Compatible with inline installations

- Clean Card Concept with enclosed design, precise sealing, and controlled extraction

Cotton nonwovens for baby and body wipes

Questions and answers about cotton nonwoven fabrics

Natural fibers in nonwoven fabric production: hemp, linen, pineapple, etc.

Plant fibers such as hemp, linen (flax), jute, and even pineapple and banana fibers are becoming increasingly important, particularly in the context of sustainable materials. Their environmental compatibility makes them attractive alternatives, especially for technical applications. Today, nonwovens made from or with plant fibers are used, for example, as

- reinforcing fibers in duroplastic and thermoplastic components in vehicle construction,

- geotextiles in earthworks for erosion control, slope remediation, carrier material for turf or facade greening,,

- dimensionally stable and breathable reinforcing elements in upholstered furniture,

- vegan leather for shoes, bags, and belts, as well as covers for furniture or car seats and

- Cleaning wipes for rougher cleaning work in workshops or industrial plants.

Advantages of natural fibers

- environmentally friendly and compostable,

- high strength, good moisture absorption, and breathability,

- small carbon footprint due to lower energy consumption and pesticide use in (regional) production compared to conventionally grown cotton

Challenges when working with plant fibers

- often higher costs than synthetic fibers,

- fluctuating, climate-dependent quality in different growing regions,

- limited availability and

- sometimes lower elasticity and softness due to coarser fibers