Höhere Produktivität, niedrigere Kosten

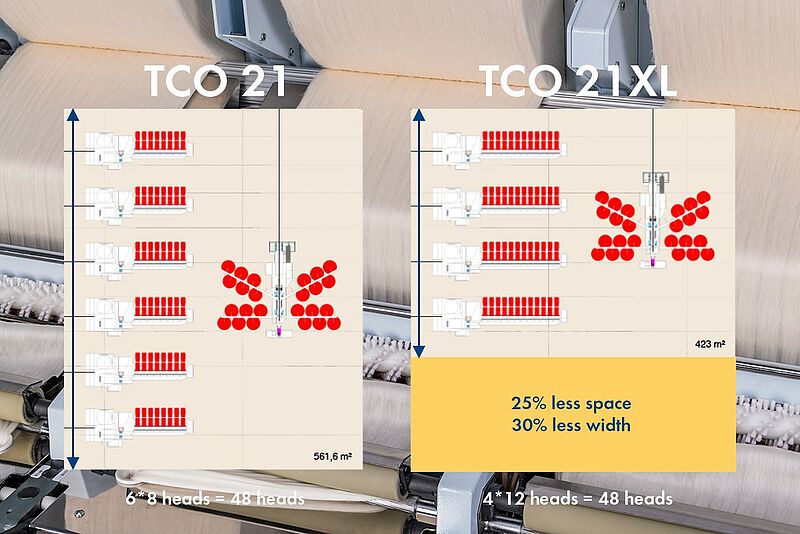

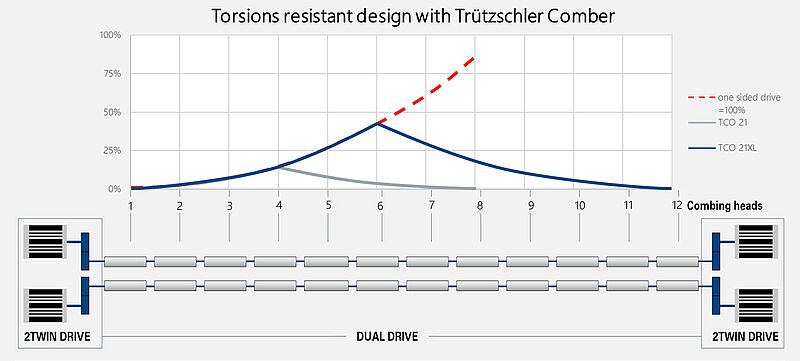

Die TCO 21XL arbeitet mit 12 Köpfen und senkt so die Verarbeitungskosten pro kg. Sie bietet 50 % mehr Produktivität bei 25 % weniger Platzbedarf. Platzersparnis im Produktionsbereich Die Breite der Spinnerei ist entscheidend:

- 30 % schmaler bei gleicher Anzahl von Kämmköpfen

Überlegene Qualität auf 12 Köpfen

Hochleistungsstreckwerk auch für 12 Bänder

- Höhere Doublierung der Bänder

- Pneumatische Belastung der Oberwalzen mit automatischer Überwachung der Grenzwerte

- Oberwalzenlagerung für möglichst niedrige Prozesstemperatur im Streckwerk

- Selbsteinstellende Wickelüberwachung der Oberwalzen

Einstellung des Lötzeitpunktes leicht gemacht

Nur Kämmmaschinen von Trützschler verfügen über eine automatische und damit saubere Einstellung der Anspinnstelle.

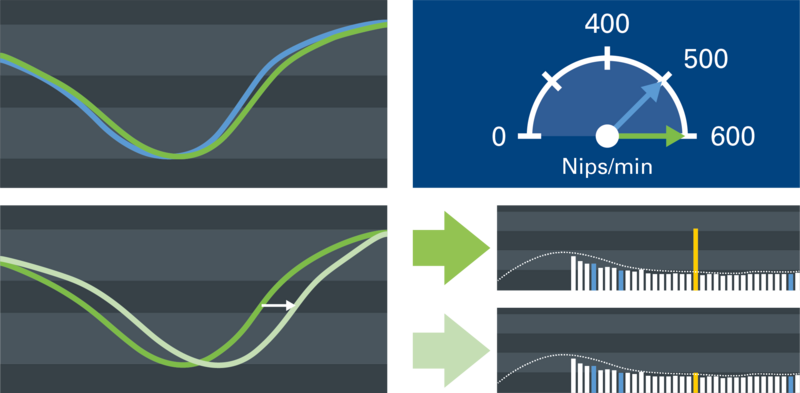

CURVE-FUNKTION

Zusätzliche Kurve, optimiert für perfekte Garnergebnisse auch bei hohen Kammspielzahlen.

Die Kurve visualisiert die Pilgerschrittbewegung der Abreißwalzen.

TIMING-FUNKTION

Automatische Optimierung des Lötzeitpunktes ohne einen einzigen Labortest für perfekte Band- und Garn-CV-Werte.

Perfekte Garnqualität durch COUNT MONITORING und COUNT CONTROL

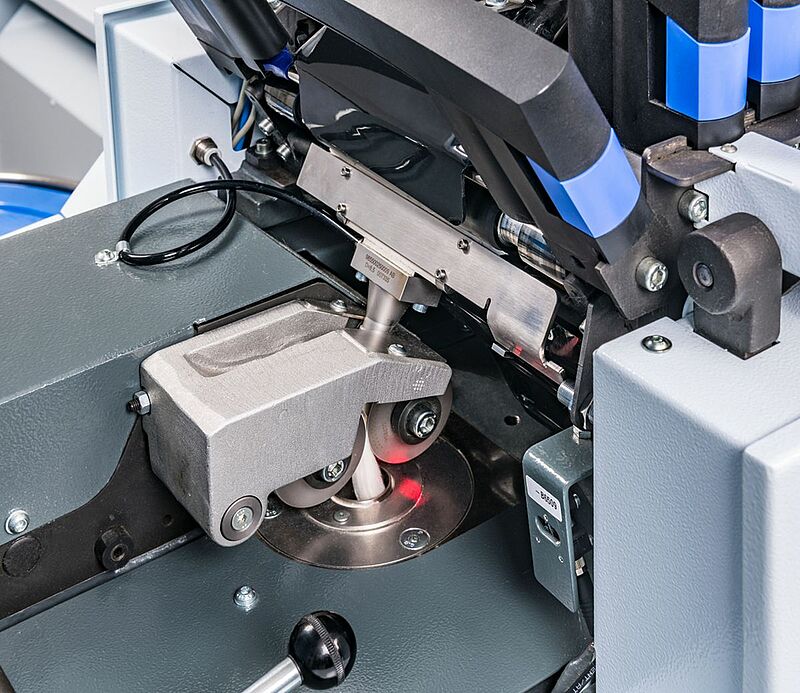

COUNT MONITORING – Standard bei der TCO 21XL

Qualitätskontrolle durch individuelle Grenzwerte für Bandnummernschwankungen – visualisiert durch T-LED. Erkennt der DISC MONITOR Sensor die Überschreitung eines Grenzwerts, gibt die Maschine eine Warnung aus und schaltet ab.

Mit integrierter Spektrogrammanalyse für höhere Qualität.

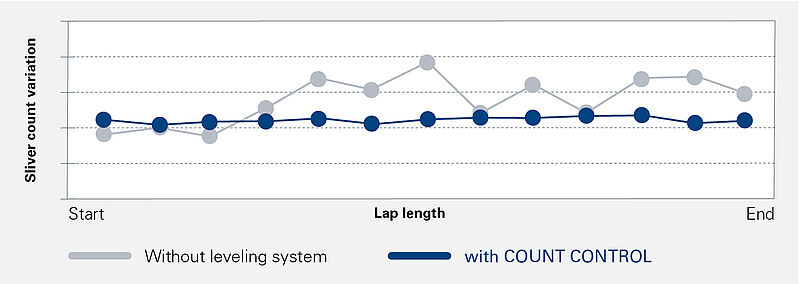

COUNT CONTROL – optionale Regulierung

Erfasst COUNT MONITORING eine Abweichung der Bandnummer, regelt COUNT CONTROL diese zuverlässig im Streckwerk aus. Die Wickelanspannung bleibt dabei unangetastet, was eine konstante Kämmqualität sicherstellt.

Das Ergebnis ist eine permanent gleichbleibende Bandfeinheit für erstklassige Garnqualität.