Der kürzeste Weg zu perfekter Qualität

Absolut gleichmäßig reguliertes Faserband

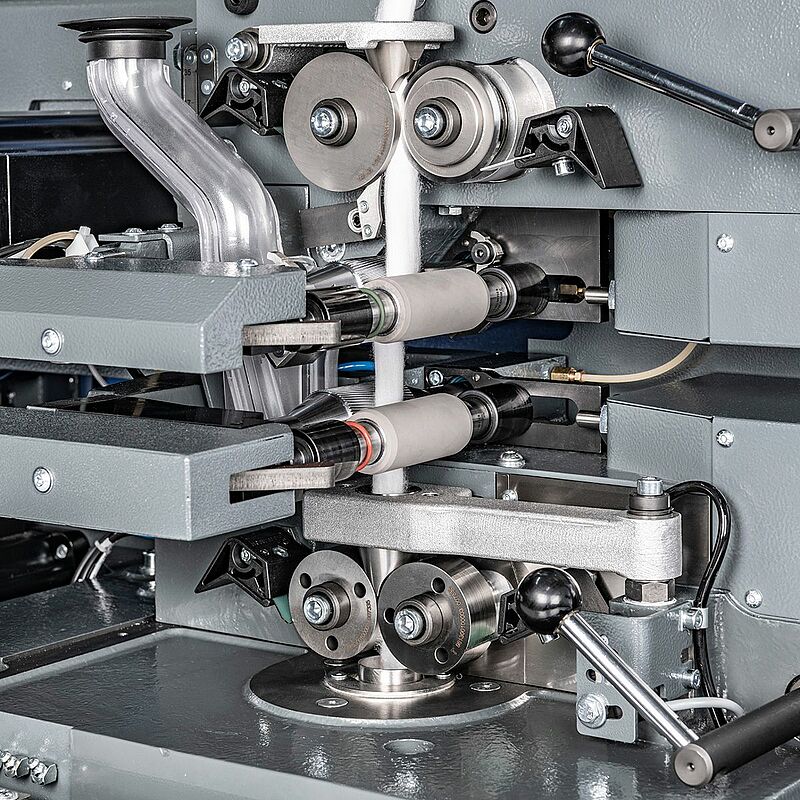

- Regeln wie eine Regulierstrecke – mit den bewährten Disc Leveller DL und Disc Monitor DM

- Weniger Verschmutzung durch Nut- und Tastwalze statt Messtrichter

Sanfte und sichere Faserführung beim Verzug

- Neu konzipiertes Streckwerk für eine sichere Führung der Fasern durch den Verzugsbereich

- Hohe Unabhängigkeit vom Laufverhalten verschiedener Materialien

Höhere Produktivität, geringere Kosten

Der Kannenwechsler ist der „Game Changer“

- Viermal höhere Kannenwechselgeschwindigkeit: bis zu 300 m/min und damit deutlich schneller als Wettbewerbslösungen – ohne dass der Ablageteller angehalten werden muss

- Beim Kannenwechsel eingesparte Zeit führt zu mehr Produktivität

Geringere Betriebskosten …

… mit dem neuen Messsystem

- Selbstreinigendes Messsystem

- Einsparung von 650,- Euro pro Jahr an jeder Maschine durch geringeren Druckluftverbrauch

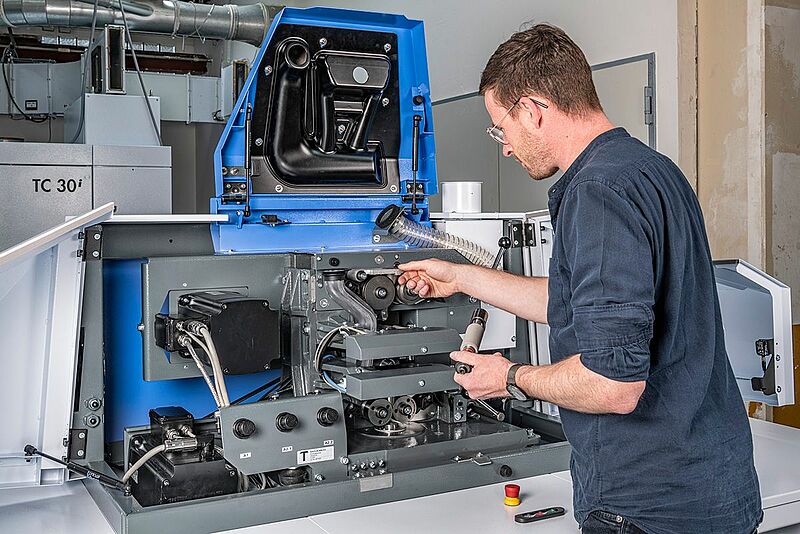

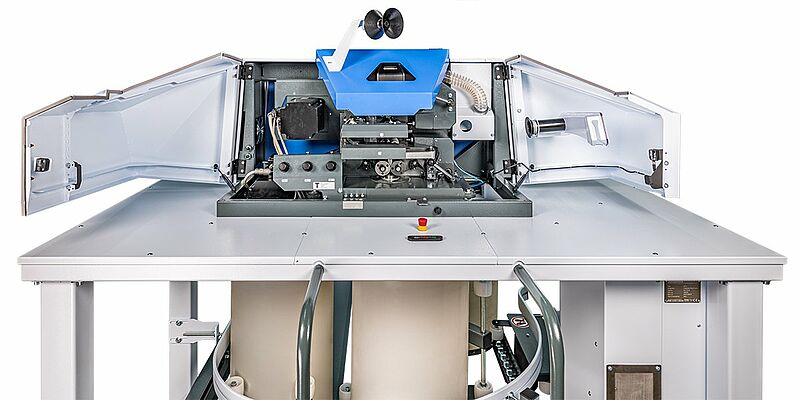

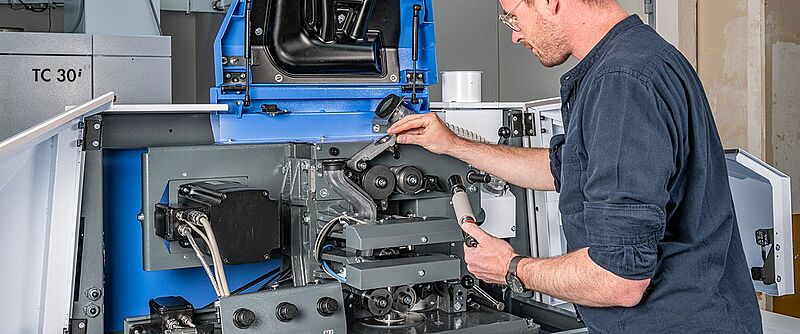

So einfach war die Bedienung noch nie

Bedienerorientierte Umgestaltung

- Die neue IDF3 lässt sich vollständig für den Bediener öffnen

- Leichter Zugang zu allen Teilen

- Zentrale Verzugsabstandseinstellung ohne Nachspannen des Riemens

- Vergrößerter Einstellbereich von 70 mm

Verschwenden Sie keine Zeit beim Anspinnen: mit dem QUICK START der IDF 3!

- Mehr als eine Stunde Handling-Zeit pro Tag und Satz* bei der Verarbeitung von Kurzfasern einsparen

- Bandbruchbehebung stabilisieren und vereinfachen

- Kein Öffnen von Abdeckungen erforderlich

* Ein Satz umfasst sechs Karden

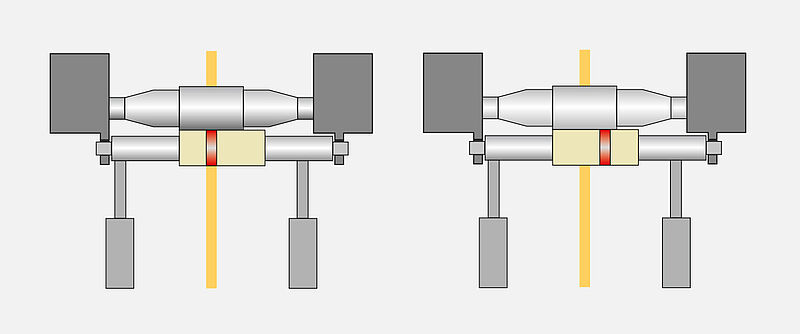

Oberwalze

- Drehbare Oberwalzen für doppelte Nutzungsdauer

- Selbsteinstellende Oberwalzen-Wickelüberwachung

- Einstellung und Überwachung von individuellen Anpressdrücken für Oberwalzen

- Hochleistungslager für geringere Prozesstemperaturen

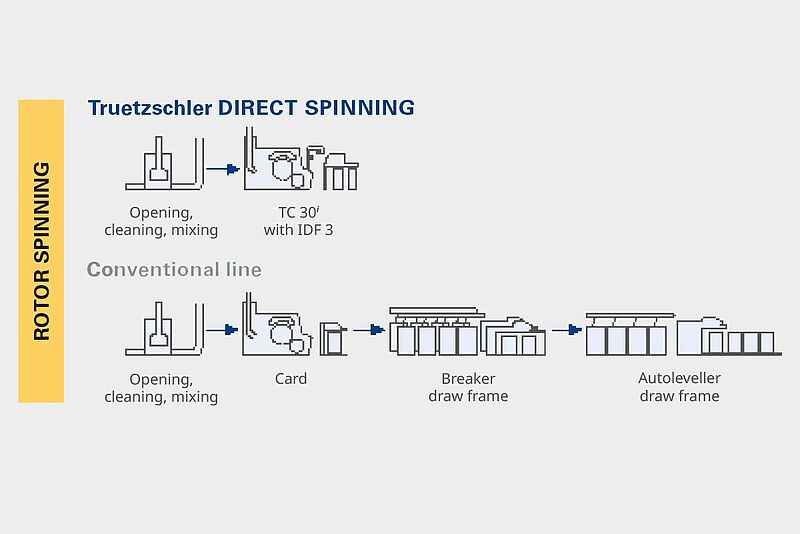

Vorsprung für Rotorgarne

Mit den Trützschler Spinnereivorbereitungsmaschinen haben Sie die Möglichkeit, 100 % Abfall zu einem hochwertigen Garn zu verarbeiten. Nutzen Sie diesen Vorteil – z. B. auch durch eine separate kleine Linie zur Verarbeitung von Spinnerei-Abfällen wie Kämmlingen aus einer Ringspinnanlage.

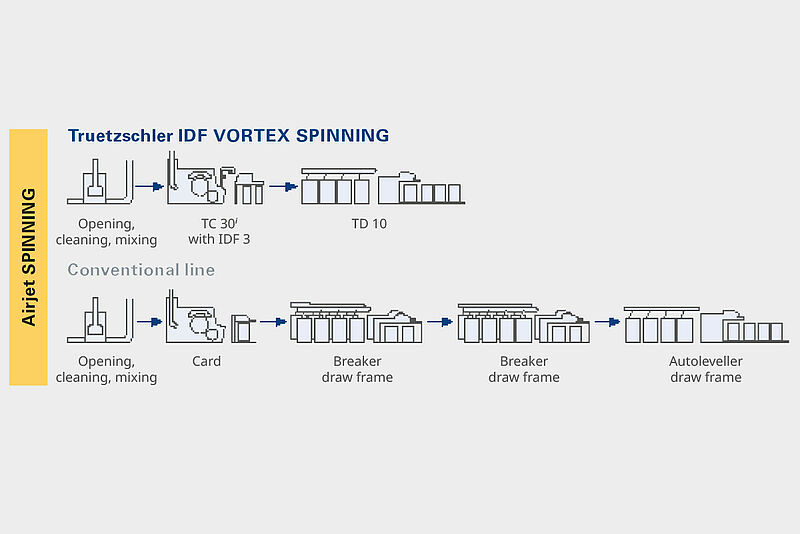

Vorsprung für Airjetgarne

Mit den Trützschler-Spinnereivorbereitungsmaschinen haben Sie die Option, den Vorbereitungsprozess drastisch zu verkürzen – auf IDF 3 und Regulierstrecke. Aber auch beim klassischen Prozess mit drei Passagen können Sie dank des effizienten TWIN BUT INDEPENDENT-Konzepts die Produktivität steigern.

Dauerhafte Einsparungen mit der IDF 3

Gerade in der Spinnerei mit ihren zahlreichen Maschinen multiplizieren sich reduzierte Prozessstufen schnell zu erheblichen wirtschaftlichen Vorteilen.

Weniger Prozessschritte bieten mehrdimensionale Vorteile:

- Geringere Investitionen

- Weniger Kapitalbindung im Prozess

- Geringerer Arbeitsaufwand

- Weniger Fehlstellen

- Platzeinsparungen