An investment in excellence

In today’s competitive nonwovens market, three factors are key: product quality, machine availability, and production performance.

Trützschler’s innovative X-Series – the NC-X, NCT-X, and NC-Xe cards – is designed to deliver top results in all three areas, boosting profitability and customer satisfaction.

The new models are based on Trützschler Nonwovens’ Elements platform.

NC-Xe, the latest card model

A base card for cost-efficient installations: Details

The new Elements platform

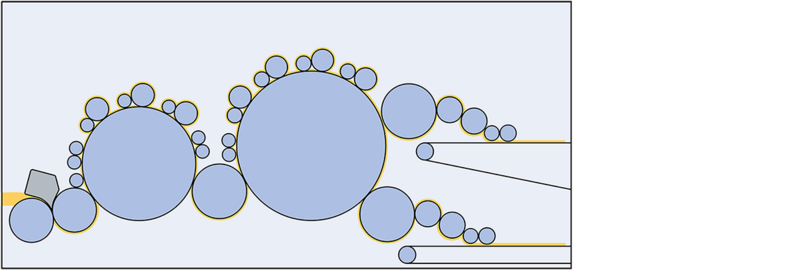

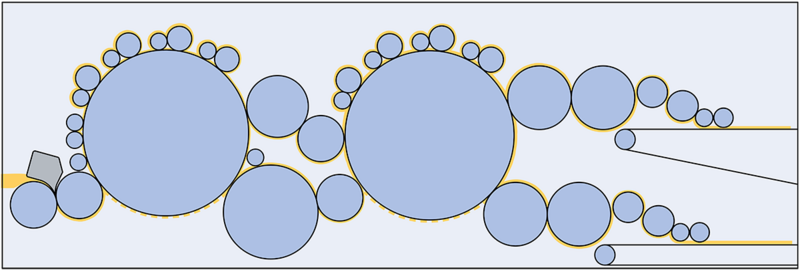

- The modular Elements carding kit reflects Trützschler’s decades of expertise in carding technology and machine design.

- Whether high-end or entry-level – all machines are built on the same technological foundation and can be tailored to the specific requirements of the end product, production process, and operating environment.

- Benefits are a unified core technology, future-proof investment and customized configurations.

Key advantages of the X-series

1. Superior nonwoven quality

- Precise fiber distribution and blending thanks to the large carding area

- Formation of uniform parallel, random, and 3D-structured webs – even at maximum speed

- High flexibility for lightweight to heavyweight products

2. Maximum availability

- Easy access for cleaning and maintenance – daily cleaning time reduced by up to 20 minutes

- Operator-friendly design with linear guides, movable modules, and dedicated tools

- Clean Card Concept to minimize fiber fly and fiber migration

3. High output and efficiency

- Maximum yield through recovery and reintegration of edge fibers

- Full working width from infeed to take-off for optimal material flow

- Clean Card Concept with tight enclosure, precise sealing, and controlled suction

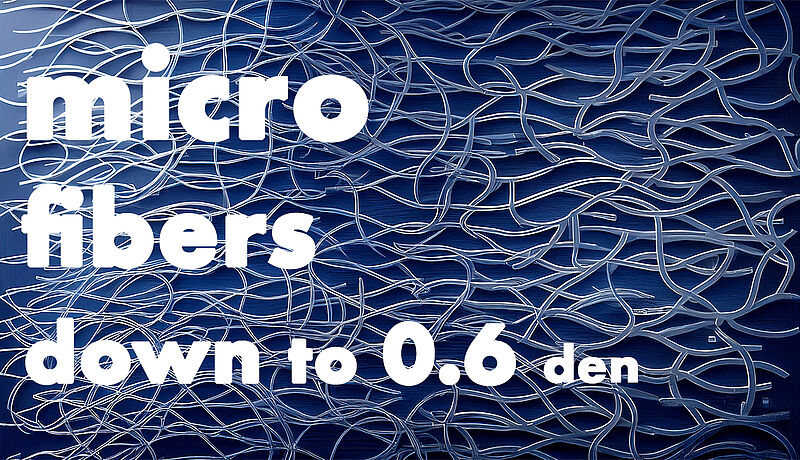

Best in class for microfibers

Equipped with NC-X cards our Air-Through Bonding (ATB) production lines set the industry benchmark for diaper topsheet and backsheet applications. Trützschler’s NC-X lines are the only installations capable of processing hygiene nonwovens with 0.6 denier microfibers at full industrial speed and productivity. Together with our customers, we pioneered this technology to enable the production of premium hygiene products.

As the quality leader, we deliver high-performance lines that empower our customers to supply the world’s leading hygiene OEMs.

.

Technical specification for NC-X and NCT-X

- Suitable for viscose, lyocell, PET, PP, bicomponent, natural, mineral, or high-performance fibers (e.g. PTFE)

- Fiber length: 12 – 130 mm

- Web weight: 14 – 135 gsm

- Fiber fineness: down to 0.6 den

- Web bonding via spunlacing (water jets), needle-punching (steel needles), or air-through bonding (ATB)

- Compatible with inline lines (NC-X, NCT-X) and crosslapper lines (NC-X)

NC-X – the versatile card for high-quality Nonwovens

Ideal for production lines manufacturing

- Needle-punched technical nonwovens such as geotextiles, filter media, or automotive textiles

- Spunlaced nonwovens for wipes, wound dressings, feminine hygiene products, or technical filtration media

- Ultra-lightweight, 3D-structured nonwovens for soft hygiene products like baby diapers, sanitary pads, or panty liners

- High-loft nonwovens for insulation, gas and liquid filtration, or protective packaging

NCT-X: a high-speed card for demanding applications

This high-performance card is specifically designed for

- Hydroentangling (spunlacing) lines with high throughput requirements

- Carded/Pulp (CP) lines for dual-layer composite nonwovens

- Fiber-intensive blending processes, e.g. for visible automotive nonwovens