Best quality from any raw material

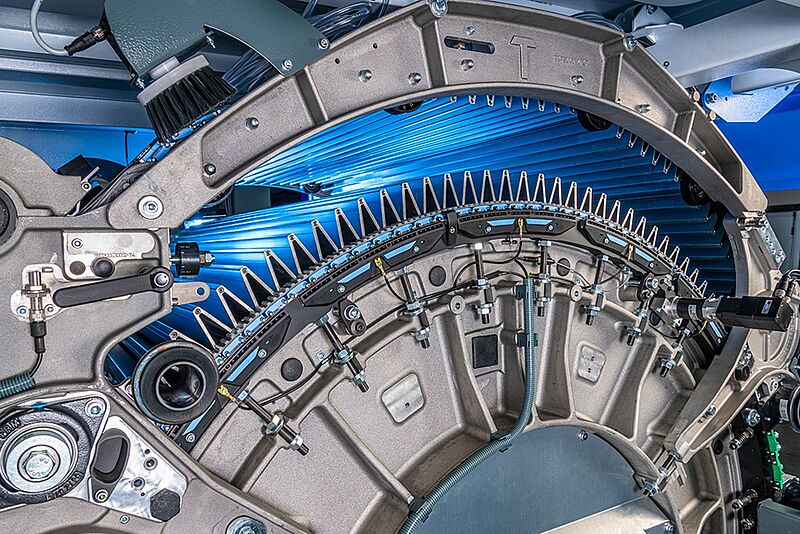

Achieve a higher level of performance and quality with 35% more active flats and a 14% extended carding length.

Operator-independent high performance with T-GO

The TC 30i comes with T-GO, the only proven and automatic gap optimizer for operator-independent efficiency. Quality and productivity can be increased via its flexible features. And it always ensures the optimal carding gap setting.

Sustainable waste handling

Create more value from waste through sophisticated waste suction. This makes it possible to reuse more than 50% of card waste. Alternatively, high-quality waste can be sold to third parties for an attractive price.

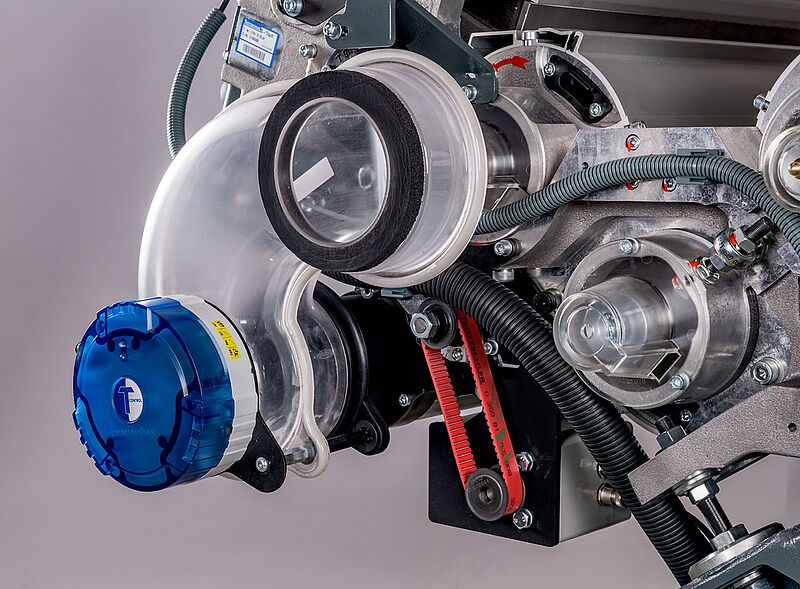

Raw material savings with WASTECONTROL

Trützschler cleaners with WASTECONTROL have ensured the best raw material utilization and minimum waste for years. From now on, WASTECONTROL is also part of the intelligent carding with the TC 30i.

The optical sensor of WASTECONTROL permanently monitors the waste quality at the most important cleaning point, the licker-in. If too many good fibers are registered in the waste, the system optimizes the mote knife adjusting system via the servo motor.

The influence of WASTECONTROL on the cost-effectiveness of carding is tremendous.

Whereas on other cards the waste separation is not measurable and cannot be influenced during production, the TC 30i always works at optimum efficiency thanks to the permanently measured data.

Operation – as simple as with a Smartphone

SMART TOUCH

The monitor forms the interface be-tween the operator and the machine. For the first time, it is designed in multi-touch technology. Operation is just as intuitive as using a Smart-phone or tablet.

Identification via personal chips

The control recognizes the person and the authorization by the chip. In this way, the operator only receives the information required for the fulfilment of his role.

More overview in the card room with T-LED

The operator can read the operating status of the machines or quality parameters at a glance from the T-LED remote display over large distances.