Rotor Spinning

Leading edge for rotor yarns

A sure way to reduce production costs is to shorten the preparation processes. Eliminating unnecessary machines saves investments and operating costs. In the rotor yarn mill, a shortened line with IDF 3 is also associated with an improved yarn quality.

The Truetzschler spinning preparation gives you the unique opportunity to process 100 % waste into a respectable yarn. Take advantage of these benefits, for instance by using a separate small line for processing spinning waste such as noils from a ring spinning installation.

The best process for your yarn

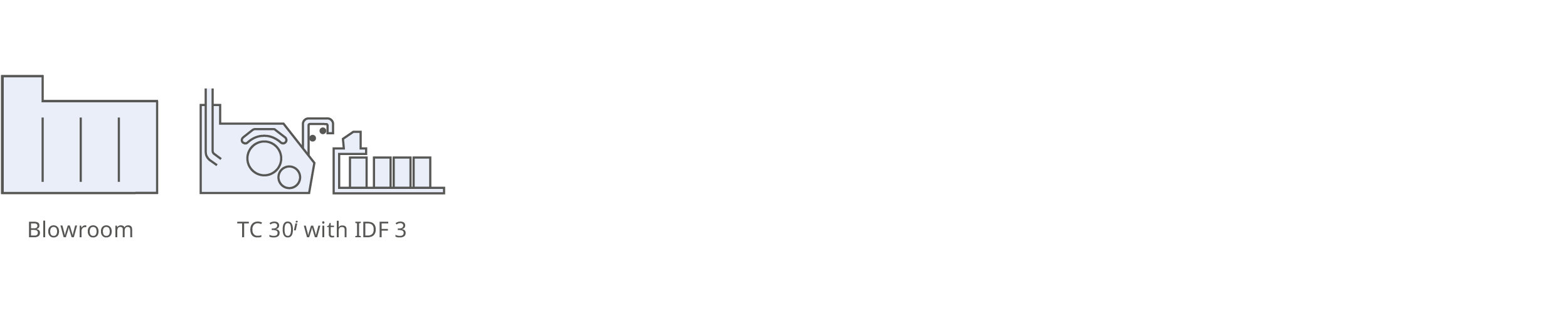

100 % cotton waste / reclaimed fibers - shortened

Increased economic efficiency through process reduction

Spinning the shortest fibers into yarn is only possible with the IDF. For example, 100 % cotton waste such as noils or production waste can be used. However, thanks to the shortened process, "second use" fibers, such as regenerated polyester or cotton fibers, can also be processed directly into a yarn.

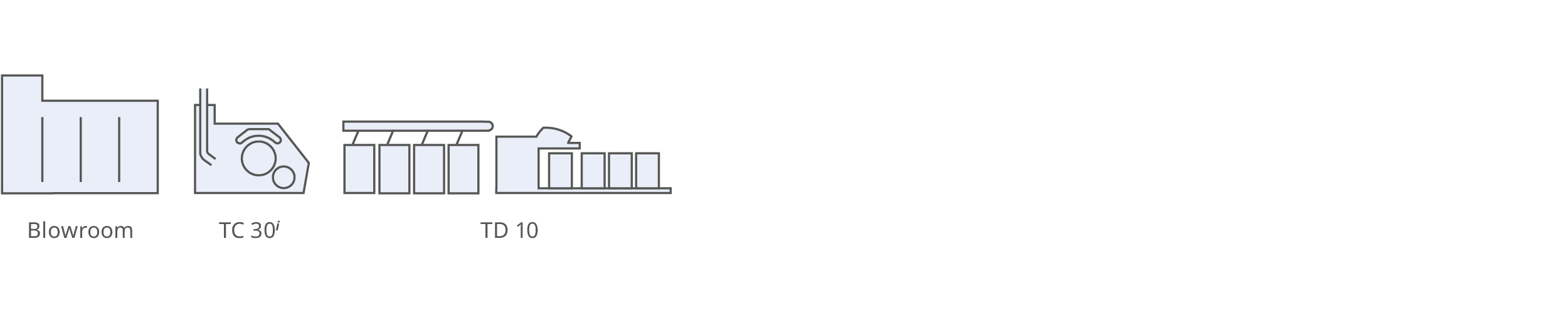

100 % raw cotton, optionally with waste - shortened

Shortened to higher quality

Rotor yarns have different properties than classic ring-spun yarns; they are more vo-luminous and have a softer handle. The properties allow the addition of short fibers, noils or cleaned waste. In the rotor yarn mill this, in combination with the shortened preparation line, is also associated with an improved yarn quality.

100 % man-made fibers / blend yarns - shortened

Perfect preparation for man-made fibers

Man-made fibers are also becoming increasingly important in rotor spin-ning. At Truetzschler, this trend is taken into account at the card and in the blowroom with stainless steel equipment for the machines. In addition, there is a special version of the TC 30i which is explicitly adapted for the processing of man-made fibers.

All materials – conventional

Classic process with innovative machines

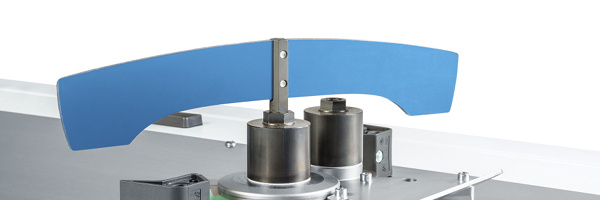

If you do not want to do without 1 draw frame passage in your process, Truetzschler naturally also offers the classic process with autoleveller draw frame. Due to its compactness and intelligent machine functions such as AUTO DRAFT, SMART CREEL and SERVO DRAFT, the TD 10 is ideally suited as a quality filter for your rotor yarn.

Blow room | Card TC 30i | Integrated Draw frame IDF 3 | Draw frame TD 10