Ring Spinning

Ring-spun yarns – valuable classics

Despite the establishment of other spinning processes such as rotor and air-jet, the classic ring-spun yarn still plays the major role in the spinning sector.

As our customer, you are confronted with rising costs, higher market demands on your end product and simulta-neously decreasing raw material qualities.

Truetzschler Spinning focuses on its core competence of spinning preparation and thus offers you the best possible solutions to emerge stronger from this area of conflict.

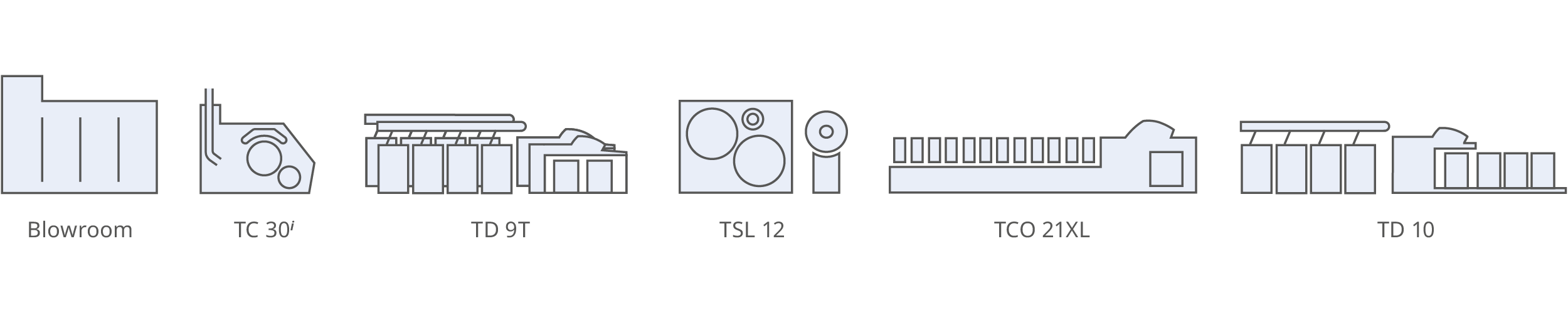

Combed cotton

The perfect cotton installation from bale opening to combing and draw frame

Combed yarns are subject to a special quality requirement. The application of the ultra-modern Truetzschler combing technologies definitely does justice to this. In combination with the intelligent Card TC 30i and the latest autoleveller Draw Frame TD you have the optimal preparation for high-quality ring-spun yarns.

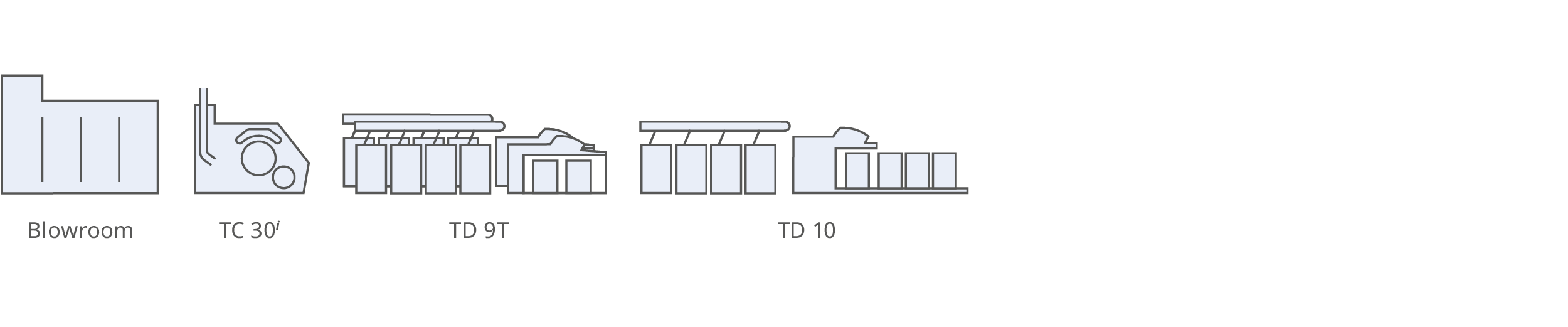

Carded cotton / Pure man-made fibers

Intelligent solutions for your ring-spun yarn

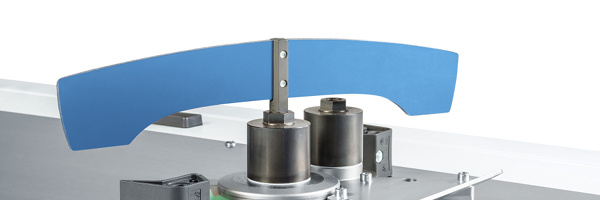

As implied by the name, with carded ring-spun yarns the card is already the centre of atten-tion. Choose the card that, thanks to T-GO, always helps you achieve the optimum carding gap and thus demonstrably stands for higher production, maximum nep reduction and better IPI in the downstream yarn process. The autoleveller Draw Frame TD 10 serves as quality filter for the spinning machines. Highly dynamic levelling intelligence has never been more compact.

Reliable processing of man-made fibers

Truetzschler offers the perfect equipment for trouble-free processing of man-made fibers with its man-made fiber version of the TC 30i. The fiber guide elements made of high-qual-ity stainless steel also lead to an absolutely trouble-free process in the blowroom. This equipment prevents the accumulation of finishing agents and thus leads to a clearly safe fiber transport. This also prevents the adhesion of fibers due to static charge.

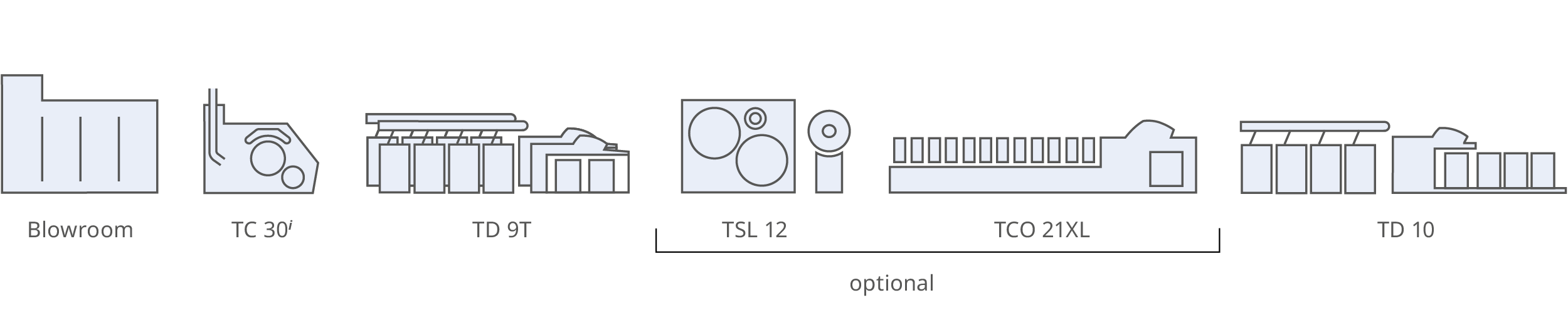

Material blends

The perfect blend

Tuft blending has clear advantages over draw frame blending by allowing you to extract the combed material if necessary and to automatically return it to the blend line as a component. Up to 3 different blends with up to 6 different components can be produced from one T-BLEND installation. And all this with maximum production and precision, thanks to the gravimetric weighing process.

Blow room | T-BLEND | Card TC 30i | Draw frame TD 9T | Superlap TSL 12 | Comber TCO 21XL | Draw frame TD 10