Higher productivity, lower costs

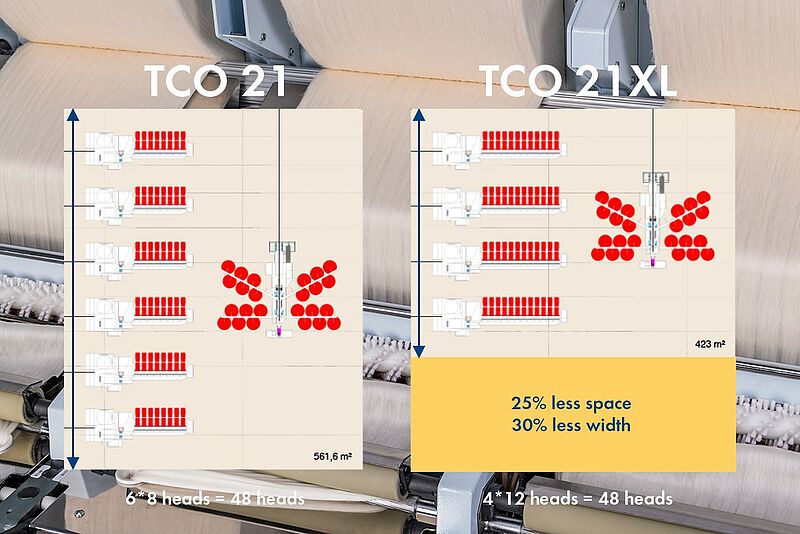

The TCO 21XL works with 12 heads, reducing conversion costs per kg. It provides 50 % more productivity while taking up 25 % less space. Space savings in the critical direction inside the mill. Mill width matters:

- 30% less building width for same amount of combing heads

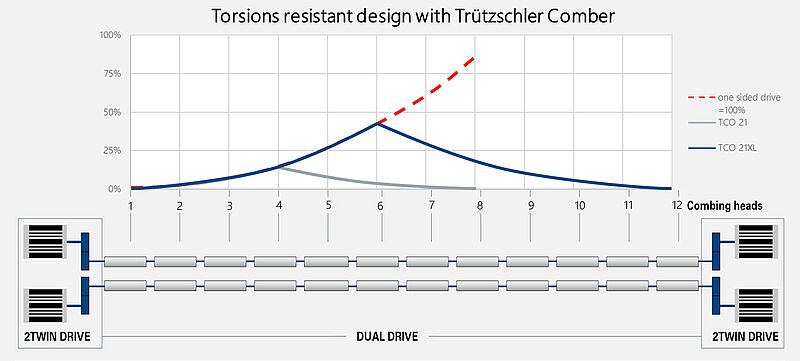

Superior quality on 12 heads

High performance drafting even for 12 slivers

- Higher doubling of slivers

- Pneumatic loading of top rollers, with automatic limit monitoring

- Top roller bearing for lowest process temperature on the drafting system

- Self adjusting top roller lap monitoring

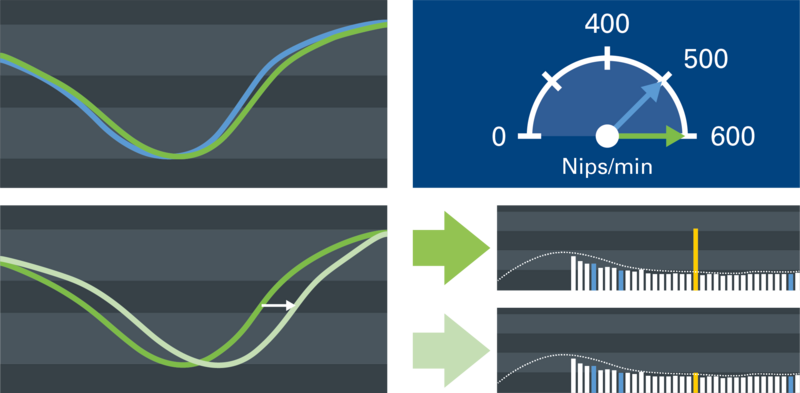

Piecing point setting made easy

Only Trützschler combers feature an automatic and thus clean setting of the piecing point.

CURVE FUNCTION

Additional curve, optimized for perfect yarn results even at high nip rates.

The curve visualizes the pilgrim step movement of the detaching rollers.

TIMING FUNCTION

Automatic piecing point optimization without a single laboratory test for perfect sliver and yarn CV values.

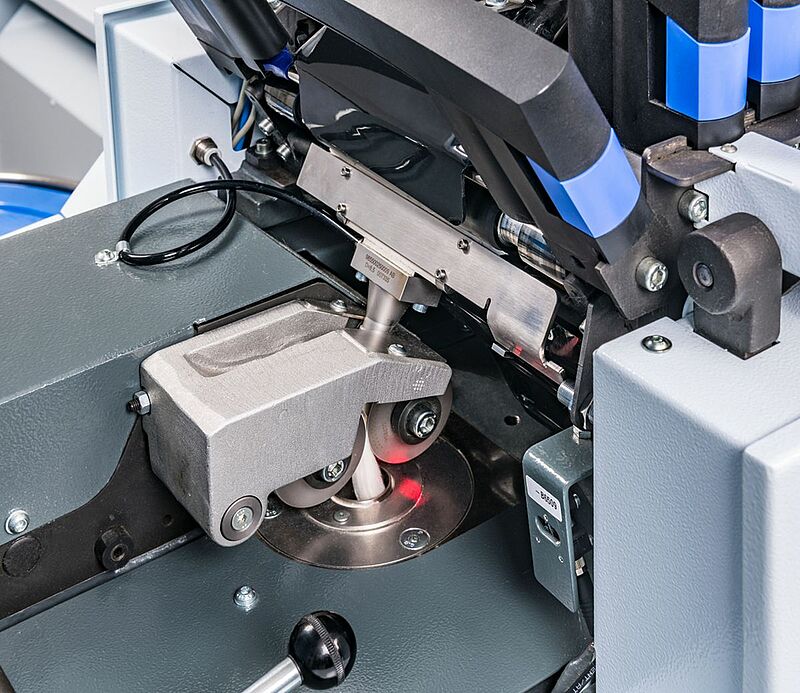

Perfect yarn quality thanks to COUNT MONITORING and COUNT CONTROL

COUNT MONITORING – standard on the TCO 21XL

Quality control through individual limit values for count variations - visualized by T-LED. If the DISC MONITOR sensor detects that a limit value has been exceeded, the machine issues a warning and switches off.

With integrated spectrogram analysis for higher quality.

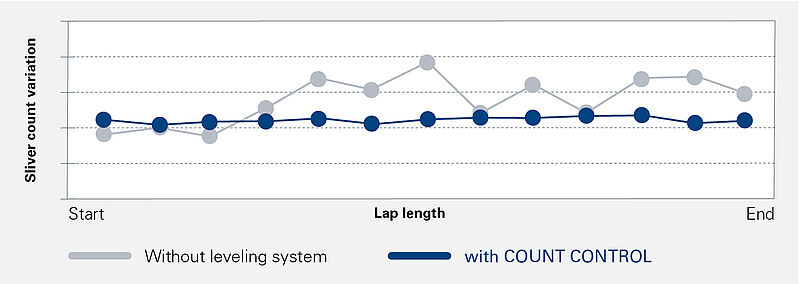

COUNT CONTROL – optional leveling

If COUNT MONITORING detects a deviation in the sliver count, COUNT CONTROL reliably levels it on the drafting system. The lap tension remains unaffected, ensuring constant combing quality.

The result is a permanently constant sliver count for first-class yarn quality.