The shortest path to perfect quality

Higher production, lower costs

Easier than ever to operate

The shortest path to perfect quality

Perfectly homogenous regulated sliver

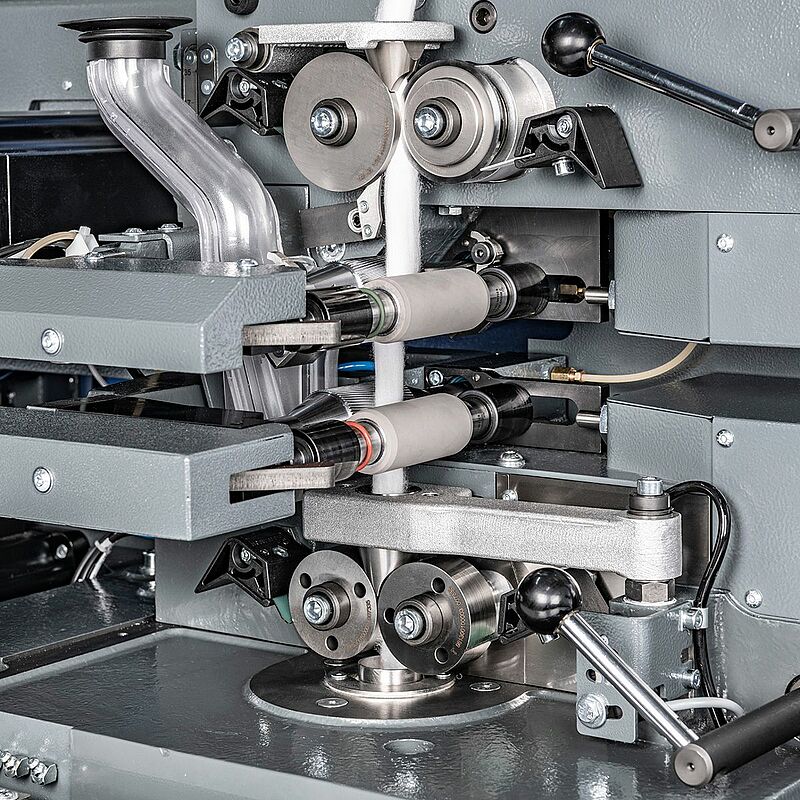

- Regulate like a finisher with proven Disc Leveller DL and Disc Monitor DM

- Reduce pollution with the groove and sensing roller instead of a measuring funnel

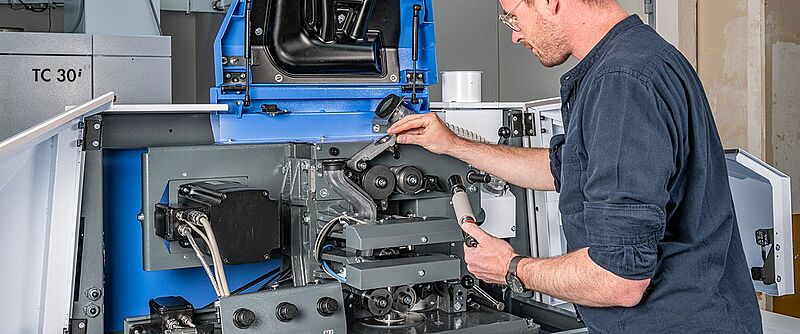

Gentle and secure fiber guidance while drafting

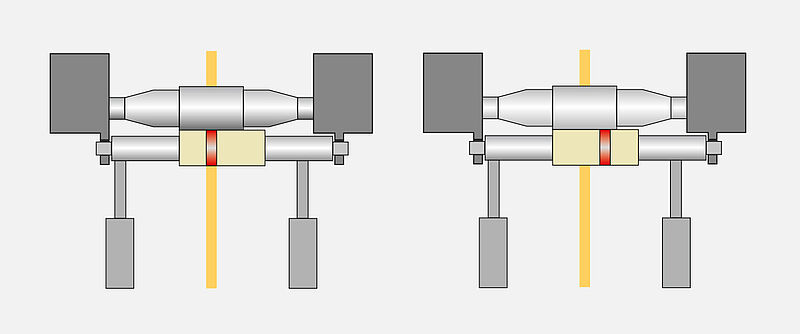

- Redesigned drafting system securely guides fibers through the drafting zone

- High independence from the running behavior of the various materials

Higher productivity, lower costs

Can changer = Game changer

- Four times higher can changing speed: Up to 300m/min, which is much faster than competitors' solutions - with no need to stop the coiler plate

- Time saved from changing cans lead to higher productivity

Decreased operating costs…

…while introducing a new measuring system

- Self-cleaning of the measuring system

- Save € 650 per year for each machine with reduced compressed air consumption

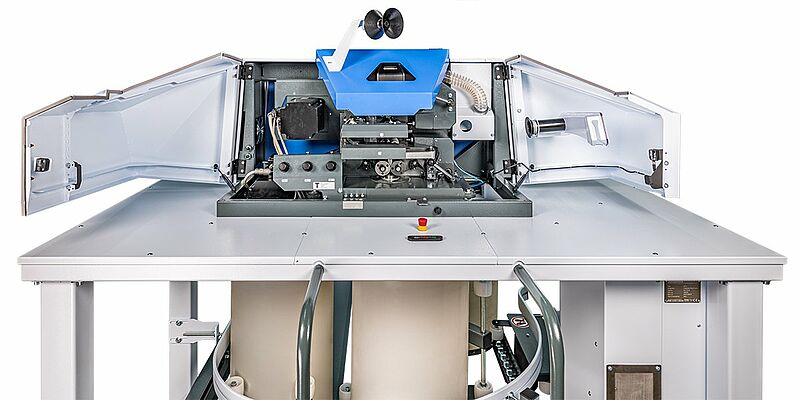

Easier than ever to operate

Operator-focused redesign

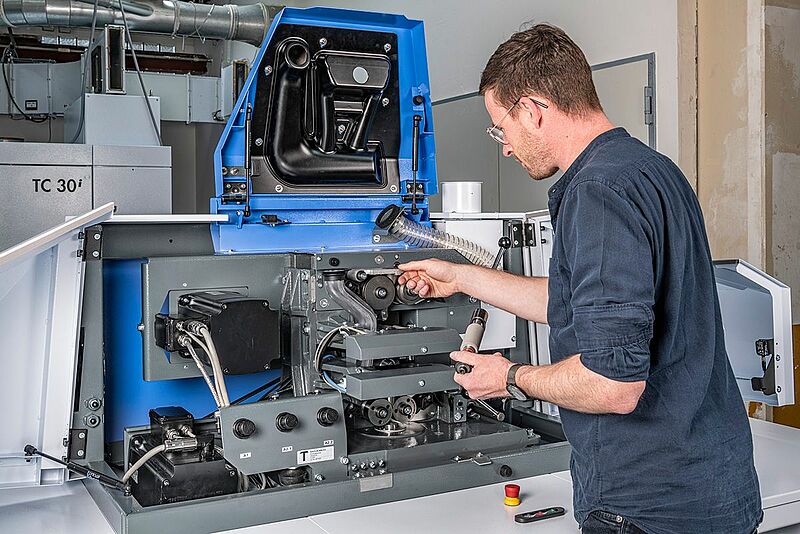

- New IDF3 opens up completely for the operator

- Easy access to every part

- Central drafting distance adjustment, without belt retightening

- Increased setting range of 70 mm

Don‘t waste time for piecing: QUICK START the IDF 3!

- Save more than one hour of handling time per day per set*, for processing short fibers

- Stabilize and simplify sliver break fixing

- No need to open any covers

*set includes six cards

Top roller

- Rotatable top rollers for double the service life

- Self-adjusting top roller lap monitoring

- Setting and monitoring of individual pressures for top rollers

- High performance bearing for lower process temperatures

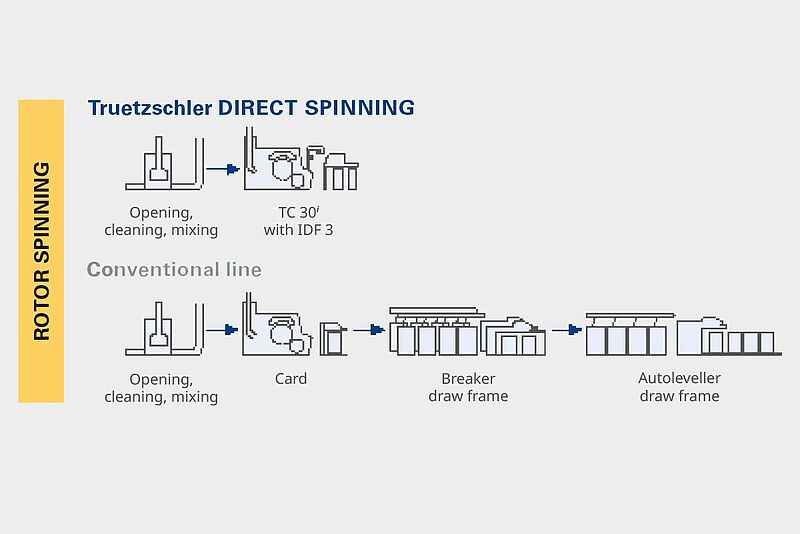

Leading edge for rotor yarns

The Trützschler spinning preparation system gives you the opportunity to process 100 % waste into a high-quality yarn. Take advantage of these benefits - for example, by using a separate small line for processing spinning waste such as noils from a ring spinning installation.

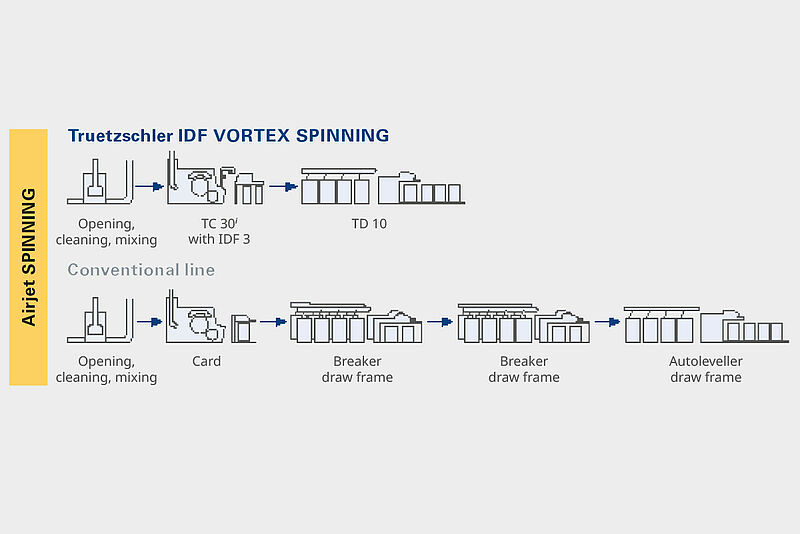

Leading edge for airjet yarns

The Trützschler spinning preparation system gives you the opportunity to drastically shorten the preparation process on IDF 3 and autoleveller draw frames. And with the efficient TWIN BUT INDEPENDENT concept, you can even increase productivity when using standard processes with three passages.

Permanent savings with the IDF 3

Reduced process stages quickly multiply to great achieve economic advantages - especially in spinning mills with several machines.

Multi-dimensional advantages from fewer process steps:

- Reduced investment

- Less tied-up capital in the process

- Reduced workload

- Minimized errors

- Space savings