Data for management

T-DATA is the real-time monitoring system from Trützschler. T-DATA provides management with solid data for the daily routine in spinning. Since the system is web-based, the data are available anytime and anywhere.

Individualisation and integration

T-DATA can be easily and intuitively individualised, precisely tailored to the requirements of the user. The system allows easy data transfer to higher-ranking customer systems.

The right data are crucial

To obtain meaningful information, it must first of all be determined. For this purpose, Trützschler developed a number of sensors.

- The optical sensor WASTECONTROL is used to monitor the waste quality of the cleaners in the blow room. This prevents unnecessary fiber loss.

- On the cards, NEPCONTROL counts the neps, trash particles and seed-coat fragments in the card web. The data allow targeted clothing maintenance.

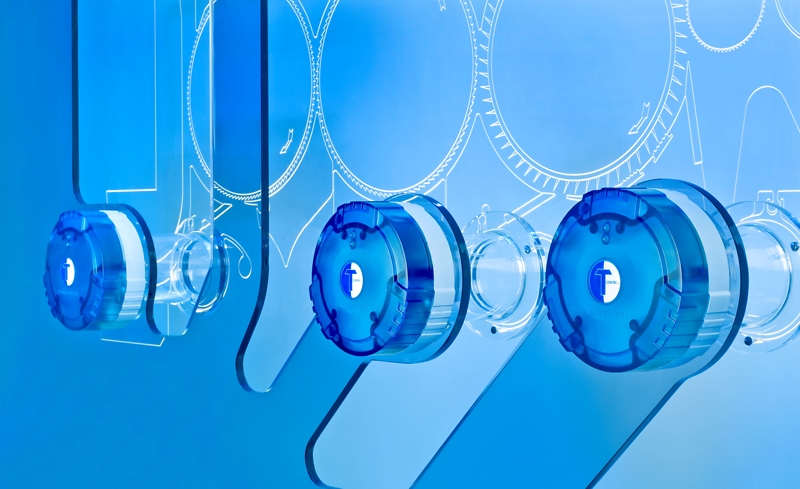

- The signals of the DISC MONITOR sensors on cards, draw frames and combers enable the early detection of emerging faults via the spectrogram analysis.

- Power consumption is monitored by special energy meters in the machines. T-DATA shows the deviating values of individual machines. This allows a very targeted maintenance.

These are only a few examples of sensors, all of which are developed and manufactured by Trützschler.