Better blending

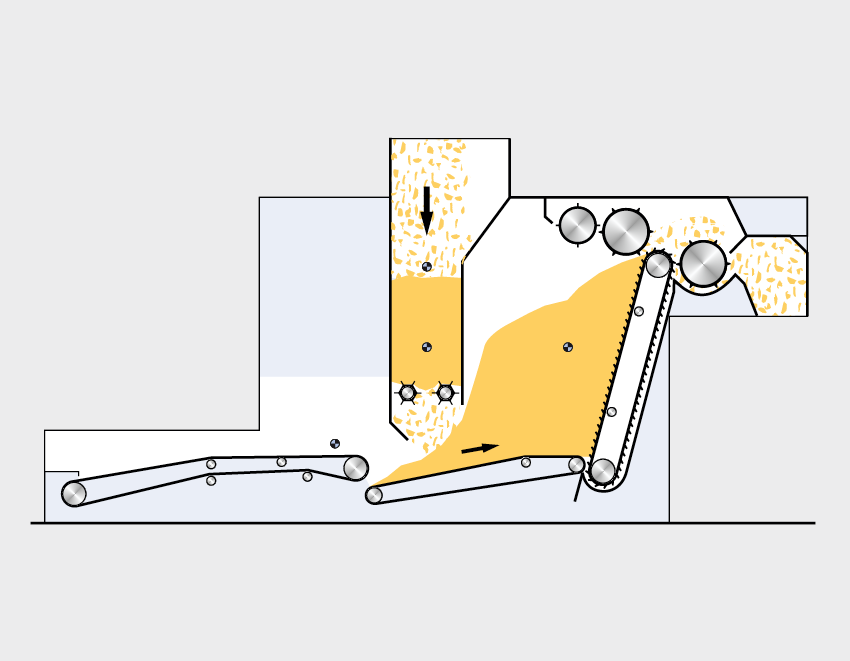

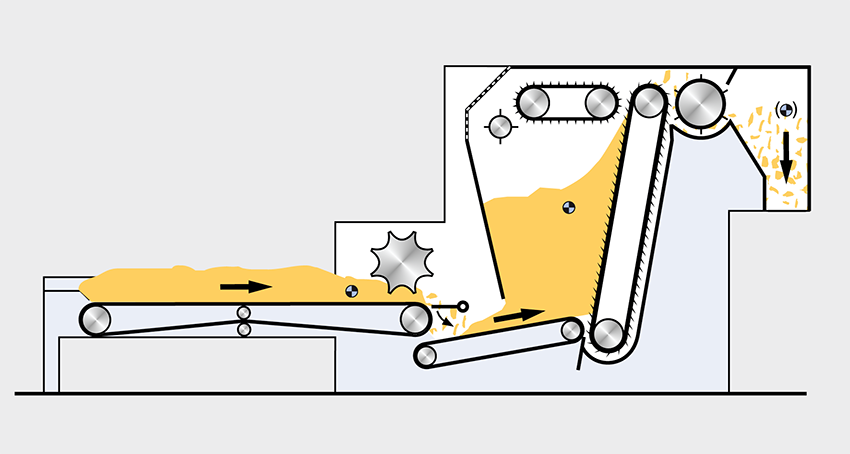

Smoother opening - smaller tufts

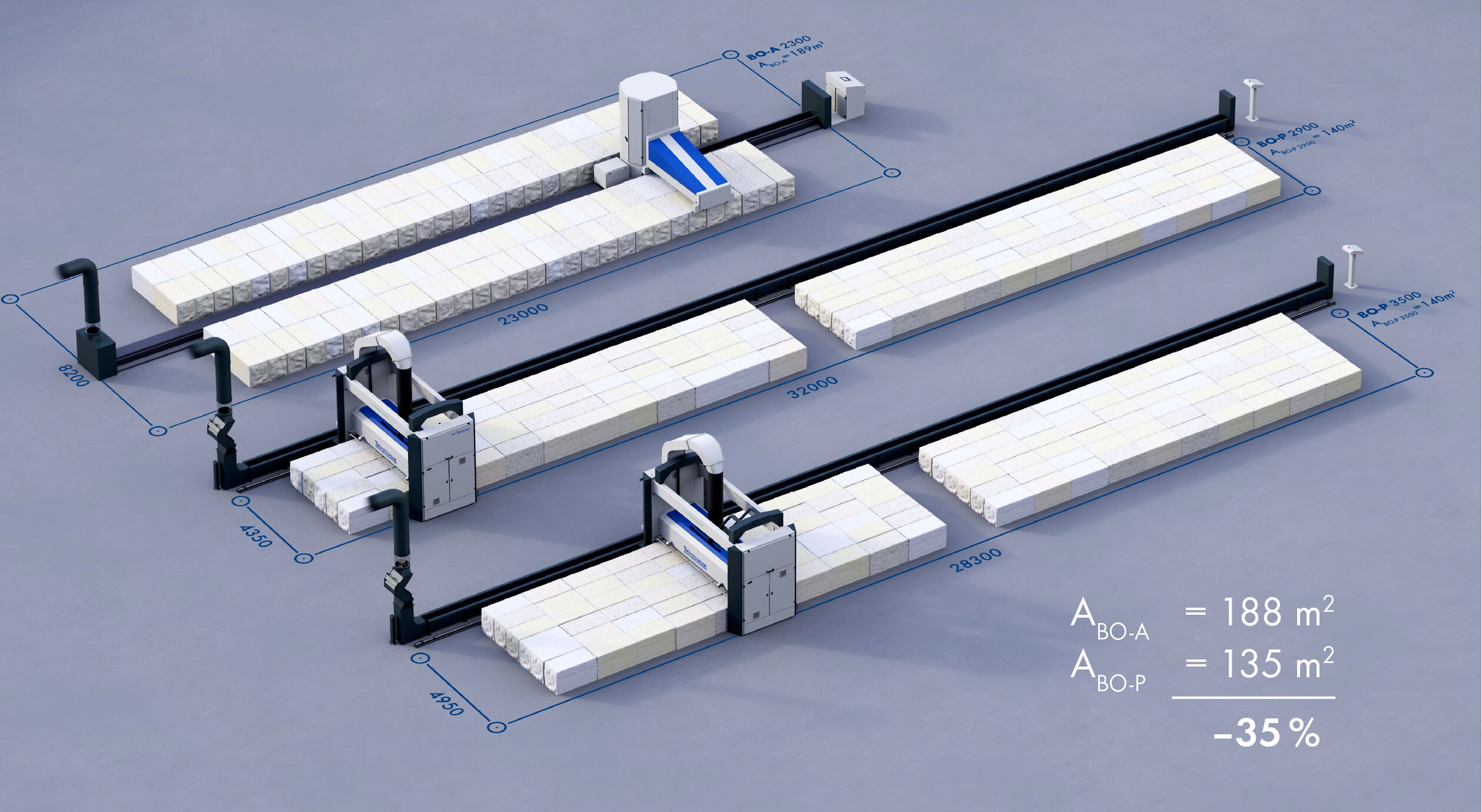

50% more production thanks to a larger working width

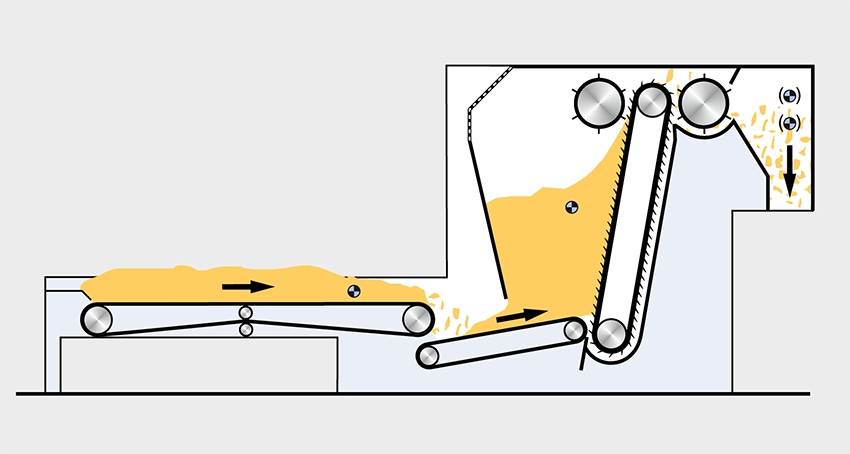

Universal Bale Opener BO-U

- The economical solution for small lots

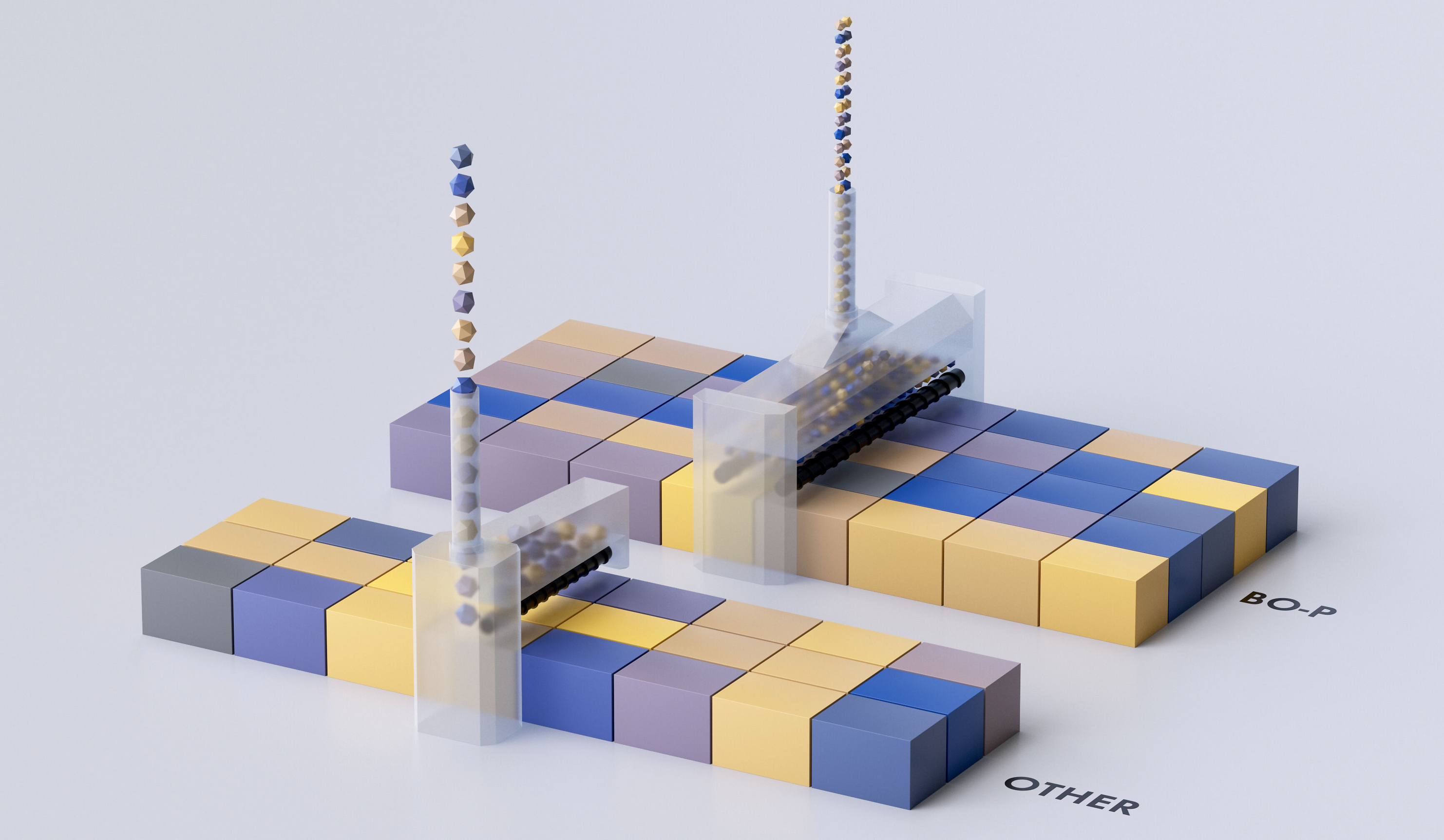

- Specific mixing of different material flows possible with additional trunks

- In supplement to BO-A, dosed addition (of cleaned waste/sliver waste) possible

Bale Opener BO-E

The smaller and space-saving Bale Opener BO-E is ideal for medium production rates up to approx. 750 kg/h. Its technology is comparable to the one of the BO-U.

Waste Opener BO-R

- The specially designed technology allows feeding of small amounts of waste such as card and draw frame slivers

- Uniform feeding possible even at minimum production of 5 kg/h

Compact Bale Opener BO-C

- Highest flexibility on smallest space by direct feeding of individual cards/card groups

- Particularly suited for opening of man-made fibres at low and medium production rates