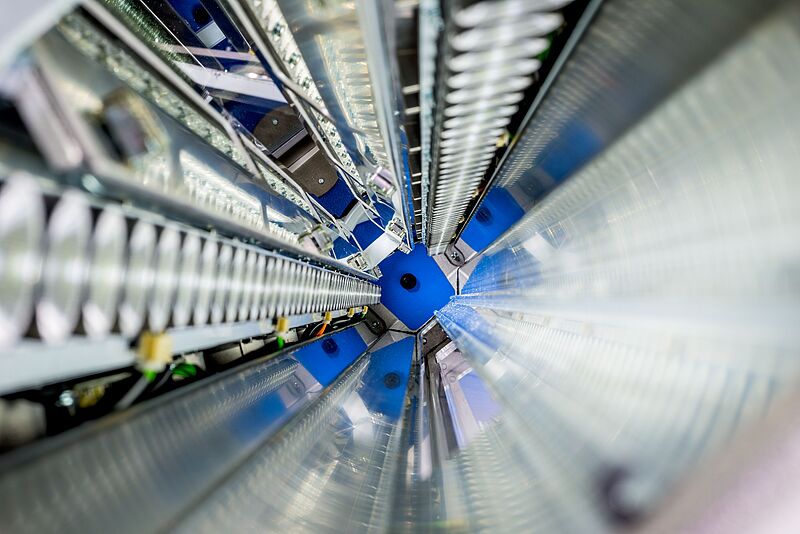

T-SCAN TS-T5

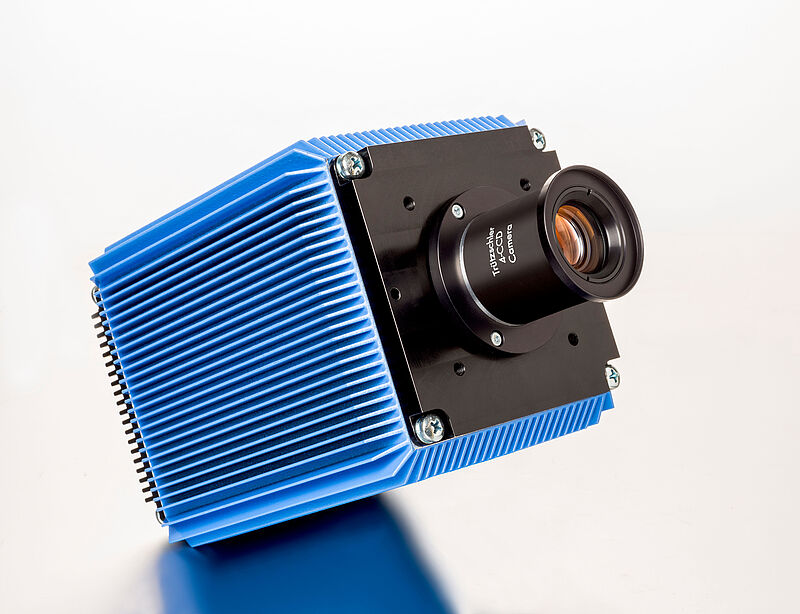

The function, number of detection modules as well as lighting technology are unique in the market. The detection of colourless and opaque, white PP is not a problem for the TS-T5.

5 detection modules

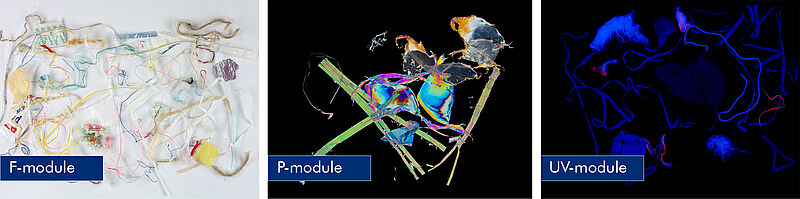

- F-module – coloured/dark foreign parts

- P-module – transparent foreign parts

- UV-module – fluorescent foreign parts

- G-module – shiny foreign parts

- LED-lighting – small/thin foreign parts

Self-optimisation with embedded image processing technology

The machine control performs a number of optimisation functions on request or permanently:

- Balancing of white reference value

- Detection of cotton colour and colour variations

- Permanent consideration of current material speed

- Stop and go detection in feeding and corresponding adjustment

Your advantages

- Detection of white PP strips

- Detection of small/thin coloured PP strips

- Low good fiber loss

- Low energy consumption

- Low compressed air consumption

- Extended service intervals

- Low maintenance costs

- Minimum space requirement

- Data transmission to the Mill Monitoring System „My Mill“

- Integration into existing cleaner lines

Foreign Part Separator T-SCAN TS-T3

The TS-T3 is a good choice if low-contrast foreign parts are no problem. Its structure is similar to T-SCAN TS-T5 and includes three modules:

- F-module – coloured/dark foreign parts

- P-module – transparent foreign parts

- UV-module – fluorescent foreign parts

DUSTEX SP-DX

If an integrated solution is not applied, the effective dust removal with a DUSTEX SP-DX machine offers:

- Higher efficiency rates

- Longer lives of clothings and spinning components

- Improved running behaviour of the spinning machines

- Increased economic efficiency of the overall installation

- Clean ambient air

This is of particular advantage to downstream processing: Thoroughly dedusted slivers ensure optimised running behaviour during yarn formation, e.g. in rotor spinning machines, but also significantly higher efficiency rates (less yarn breaks) in winding, knitting, warping and weaving.