High productivity up to 600 nips/minute

The Comber TCO 21 achieves a high combing speed of 600 nips per minute with stable running behavior and minimal vibration.

This is made possible by the drive technology specially developed for the TCO 21 in Germany.

Perfect yarn quality thanks to COUNT MONITORING and COUNT CONTROL

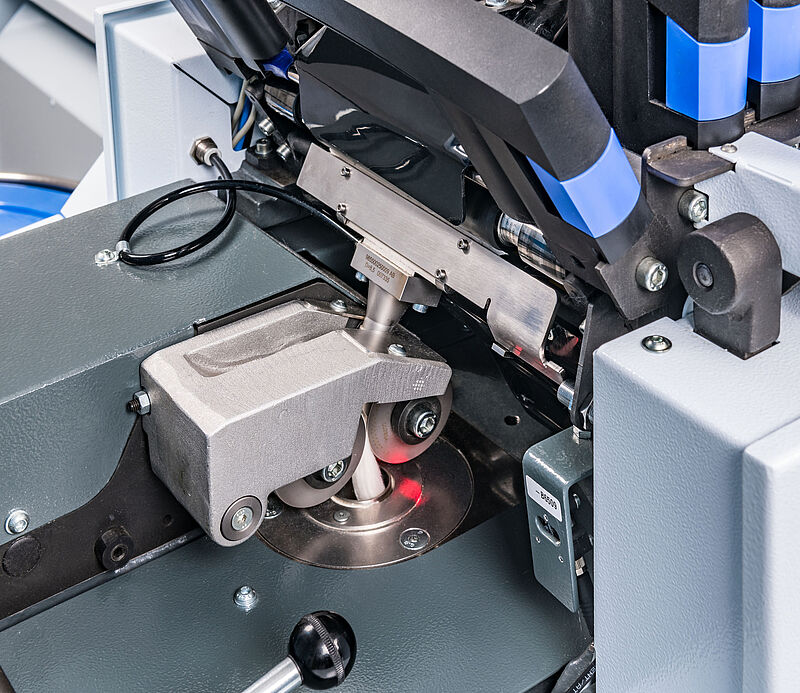

COUNT MONITORING – standard in TCO 21

Quality control through individual limit values for count variations - visualized by T-LED. If the DISC MONITOR sensor detects an exceedance, the machine issues a warning and switches off.

With integrated spectrogram analysis for higher quality.

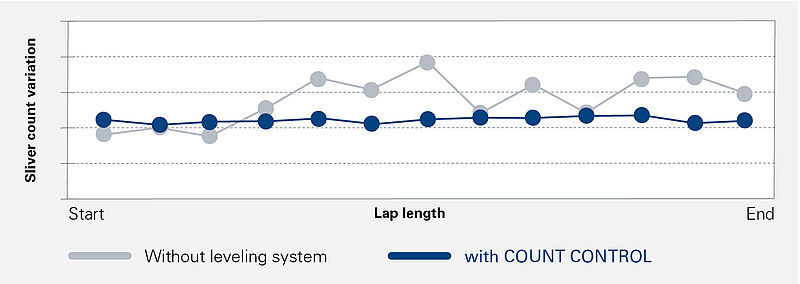

COUNT CONTROL - optional leveling

If COUNT MONITORING detects a deviation of the sliver count, COUNT CONTROL reliably levels it in the drafting system. The lap tension remains unaffected, ensuring constant combing quality.

The result is a permanently constant sliver count for first-class yarn quality!

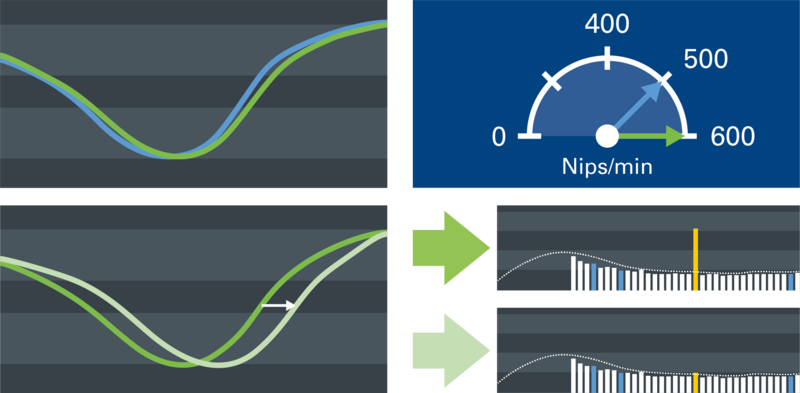

Piecing point setting made easy

Automatic optimization via the PIECING OPTIMIZER: A clean solution

Only the Trützschler combers provide an automatic and thus clean setting of the piecing point.

CURVE-FUNKTION

Additional curve, optimized for perfect yarn results even at high nip rates.

The curve visualizes the pilger step movement of the detacher.

TIMING-FUNKTION

Automatic optimization of the piecing point without a single laboratory test for perfect sliver and yarn CV values.