Autoleveller Draw Frame TD 10

TD 10 – a building block in the Smart Factory

Self-optimizing features are the key in the world of tomorrow, where high operator fluctuation is already a reality, and with it a loss of important quality know-how.

The quality filter in the spinning mill

The high-precision levelling of the draw frame sliver in the last draw frame passage is decisive for the quality of the subsequent yarn. For this reason, Trützschler has further optimized levelling in the new draw frame model TD 10 and thus once again set a benchmark in draw frame technology.

In combination with the mill monitoring system “My Mill”, the quality sensors DISC MONITOR and DISC LEVELLER, which are checking every metre of draw frame sliver, are the building block of a Smart Factory.

A better overview of draw frames with T-LED

The operator can read the operating status of the machines or quality parameters at a glance from the T-LED remote display over large distances.

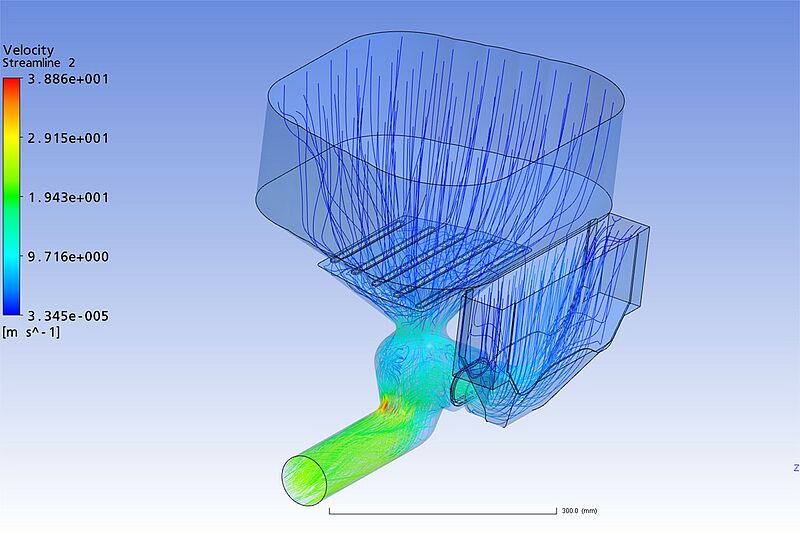

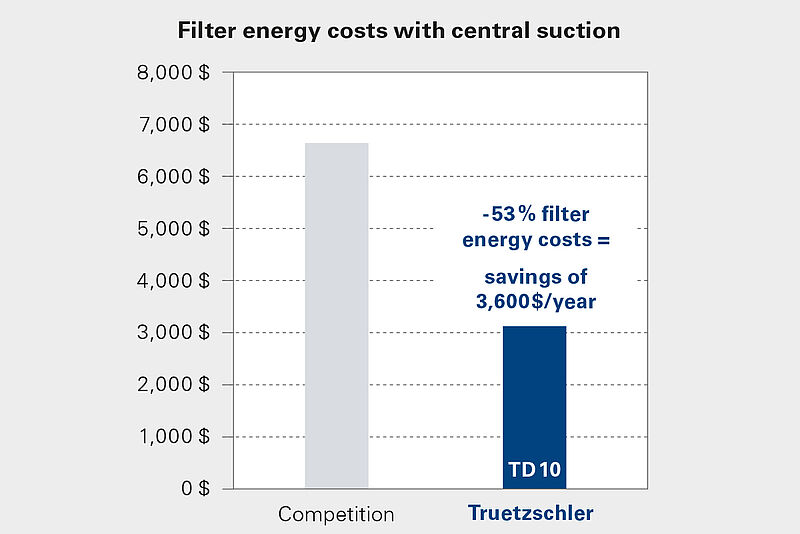

The world’s most energy efficient suction system

If the draw frames are connected to a central filter system, enormous savings potentials can be realized here as well. Due to the flow-optimized suction ducts, the TD 10 requires only a volume flow of 840 m³/h at a pressure of merely -430 Pa. This results in a significantly reduced filter load and thus in significantly lower energy costs. Savings can also be realized to the same extent on the breaker draw frames.

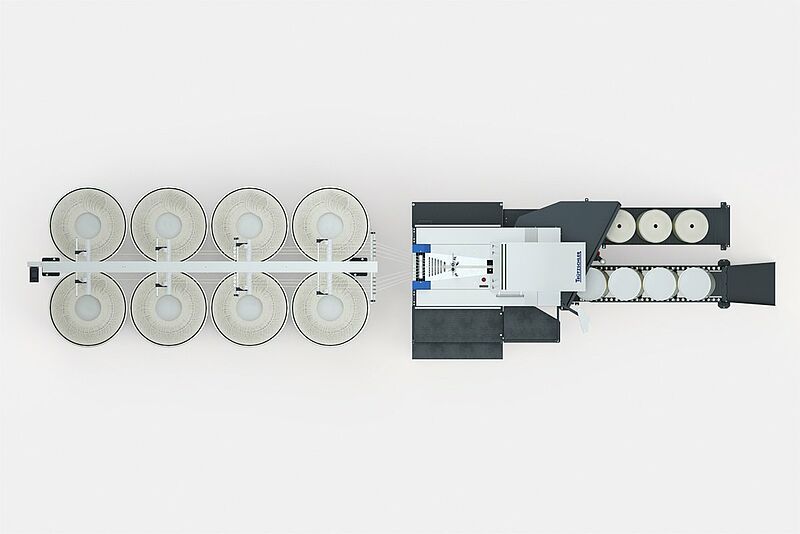

The new compactness

Because length matters

The length of the draw frames is decisive for the length of the building and thus also for the investment and operating costs. This is why the TD 10 is optimized for compactness: The new design made it possible to shorten the machine by 335 mm.

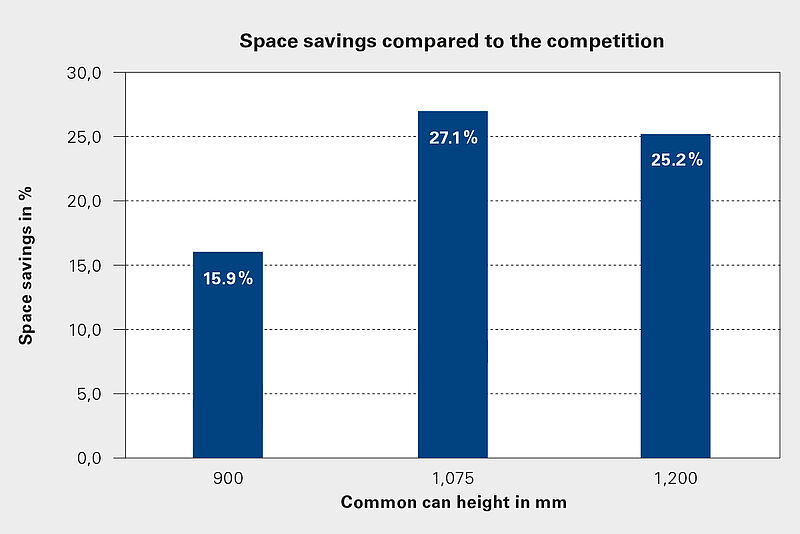

Space savings of more than 20 %

Compared to the competition, the space saved by the clever design of the TD 10, averaged over all can heights, is more than 20 %.

This means that a spinning mill with a draw frame production of 1,000 kg/h can achieve savings in building investment of up to $ 14,500.

TD 10C „Compact“

The Trützschler double head concept stands for separate drives and maximum efficiency. For autoleveller draw frames there is therefore the COMPACT installation of the TD 10 with the advantages of a double head draw frame regarding space requirements and independence from individual machines in terms of production output.