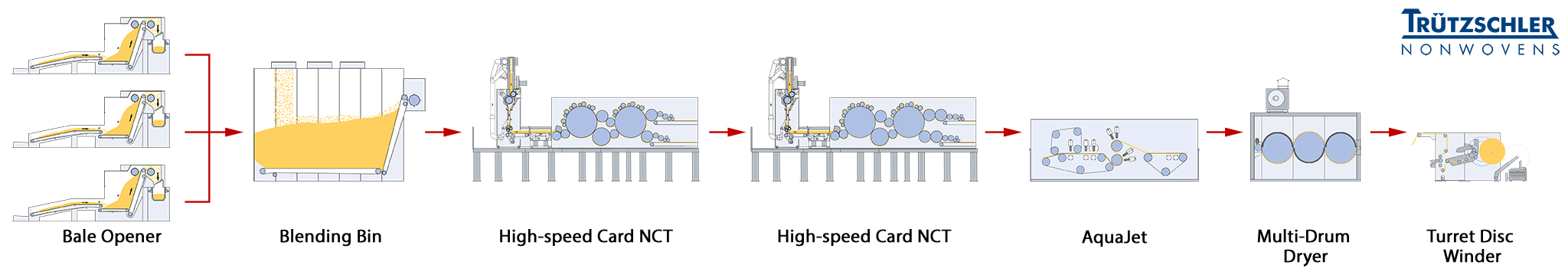

Several roller cards for higher capacities

Inline systems are characterized by at least two cards in a row.

Only the use and combination of several web formers - be it the standard card TWF-NC, the random card TWF-NCR or the high-speed NCT card - enable highest throughputs.

Line characteristics:

Typical web weights: 30 to 100 gsm

Fibers: PET, PP, viscose and their blends

Output: more than 20,000 tons/year

(depending on fiber type, web weight and working width)

Typical end products: dry and wet single-use wipes

The success factor: efficient web forming

High production speeds are particularly critical for the carding and web formation process. Fiber fly and distortion of the unbonded fiber mat must be minimized in order to produce a homogeneous fleece.

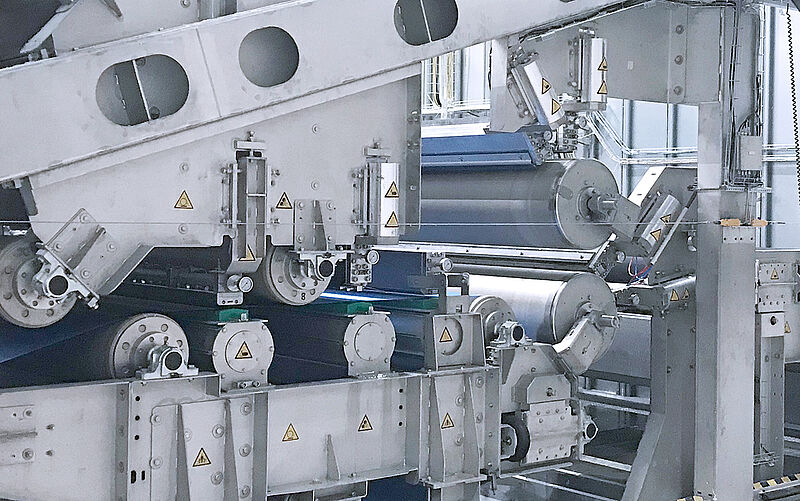

The key component for maximum throughput is the high-speed card TWF-NCT. An enlarged pre-cylinder and an innovative roller geometry significantly increase carding and blending performance.

Other key components

The AquaJet for hydroentangling is designed for speeds above 400 meters / minute.

The TWD-MDD multiple drum dryer is scalable – another drying drum can be added if needed. This guarantees energy-efficient drying in a small space, even at high production speeds.

High-performance systems also for environmentally friendly nonwovens

If only viscose or lyocell fibers are used, the spunlaced nonwovens are 100% biodegradable. Soil bacteria decompose them in the course of a few weeks without leaving any residue - what remains is water, minerals, gases and biomass.